|

|

|

04-02-2024, 02:35 AM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

sourcing cast bullets

sourcing cast bullets

My gun prefers 6 grains red dot, and matts .430 diam 240 swc.

I still get leading when i go with hotter loads, and have been considering gas checks or coated bullets. both when priced made me start choking on my tongue.

I ran across a thread on a different forum, not a member on as mentioning the use of store bought lead bullets from a non paying vendor gets you account locked.

The thread was that one can apply a gas check to ANY cast bullet, regardless of if the cast bullet came from a bullet mold intended for gas checking.

I am merely asking if that is even close to true.

|

04-02-2024, 03:40 AM

|

|

Suspended

|

|

|

Join Date: Jan 2007

Location: Sandy Utah

Posts: 8,747

Likes: 1,590

Liked 8,918 Times in 3,555 Posts

|

|

Yes, it is true, but I have no recollection of who sells the tools as I lost the information when an earlier computer crashed. The checks are made from thin aluminum such as beer cans so the material is easily crimped on the bullet. Try "Googling" gas check making, or contact/join the "cast Boolits.com" web site.

Before going to the trouble buy some Lee Liquid Alox (LLA) and re-lubricate the bullets. There are two things that prevent leading with cast bullets, proper sizing and proper lubrication. Most commercially available cast bullets fail on both counts, but the LLA will help with one of them.

Cast bullets should be sized 1-2 thousandths of an inch over barrel groove diameter and for revolvers the cylinder throats. Most commercial bullets are too small!

|

|

The Following 3 Users Like Post:

|

|

04-02-2024, 03:43 AM

|

|

Member

|

|

|

Join Date: Mar 2012

Location: Upstate, SC

Posts: 2,038

Likes: 3,130

Liked 4,825 Times in 1,546 Posts

|

|

No, you cannot use traditional gas checks on a non-gas check design cast bullet.

There have been attempts at other alternatives, such as "soft gas checks". These come in sheet form, and are made of a wax-like substance. You cut them out like a cookie cutter and they stick to the base of the bullet.

The key to cast bullet success in revolvers has not changed in over 100 years.

-Determine cylinder throat diameters and bore diameter. Ideally, they match, or the throats are .001-.002" (max) larger than bore diameter.

-Cast bullets are then cast from a mold and alloy combination so they either drop from the mold exactly matching throat diameter to no more than .002" larger.

There might be some experimenting needed in bullet sizing: generally either match the throat diameter, or size to .001" more.

In the great old days when Hensley & Gibbs were in business, you could tell them the alloy you use and the bullet diameter you want, and they would cut you a mold that would drop bullets you could load "as cast"!

Loading die choice is important! Again, back in the great old days, you could order a Star Universal progressive press and tell them the exact cast bullet diameter you would be using with your chosen brand of brass. They would tune and install correctly fabricated a sizing die and expanding plug so you got perfect loads with no damage to the bullet.

Many dies today are made to work best with jacketed bullets using a very hard grip on the bullet. In other words, they undersize your brass tremendously.

Seat you nicely sized cast bullets using such a die set, and you will find they are ruined!

Don't believe me? Here's a test:

Make a dummy round, then pull the bullet with kinetic bullet puller. If your dies are good the pulled bullet will be the same diameter, and without a choked base (!), as when it was loaded. If your dies are too tight you'll find the bullet has been distorted and squeezed down by .002" or more. Often, the base will be smaller than the driving band.

Result:

Goodbye accuracy, Hello leading!!

The remedy is die modification. Too much to go into here!

But you get the idea.

Technique and informed measurement beats out simple truisms about hardness, gas checks, coatings, etc.

That's why best cast bullet performance is achieved with your own cast bullets, provided you do your research. Store bought bullets are not only really expensive, but you can't count on someone else paying due diligence when they're trying to make a buck!

It is very possible to get great cast bullet performance with medium soft alloys and old-fashioned alox-based lubricants if you get your gun, bullets and dies all matched to one another.

|

|

The Following 7 Users Like Post:

|

|

04-02-2024, 08:49 AM

|

|

Member

|

|

|

Join Date: Nov 2001

Location: USA

Posts: 195

Likes: 114

Liked 123 Times in 70 Posts

|

|

Coat bullets with Lee Liquid Alox. Best results in applying liquid Alox are when the Alox is heated before applying, or thinned with mineral spirits to maximum of 1 part mineral spirits to 10 parts Alox. This makes it flow more easily, and results in a more even coat. One technique is to boil water and pour it into a coffee mug, and then drop the bottle of liquid Alox into the mug for about five minutes.

Place your freshly cast bullets into something about the size of a Cool Whip bowl and drop a few drops of liquid Alox on the bullets. Mix the bullets around until they are all coated. Lay the freshly coated bullets on some wax paper to dry. Liquid Alox will usually dry enough overnight to reload the next day, depending upon the humidity.

If you subscribe to the "more is better" line of thought, your coated bullets may never dry. Don't go for a "golden" color but rather just a light varnish. If you discover that your bullets are sticky the next day, you can get by with using a little less the next time. Keep reducing until the "stickiness" is gone by the next day. Tacky bullets can be dusted with powdered graphite

|

04-02-2024, 09:45 AM

|

|

Member

|

|

|

Join Date: Feb 2017

Posts: 35

Likes: 82

Liked 22 Times in 14 Posts

|

|

I cast my own .430 LSWC projectiles, powder coat them, lube them, size them and then hot load them with 20 grains of 2400 powder! No leading and very cheap to produce. However, it does take a big commitment in time, but if you do it in big batches it’s very efficient.

I feel like the combination of powder coating and lubing lets me shoot cast lead bullets at magnum velocities with no leading. My lube is home made 45-45-10 and my alloy is water quenched clip on wheel weights. The powder coat is Eastwoods hot coat gloss clear.

|

|

The Following User Likes This Post:

|

|

04-02-2024, 10:58 AM

|

|

Member

|

|

|

Join Date: Nov 2005

Location: Metamora, Michigan

Posts: 760

Likes: 279

Liked 1,118 Times in 385 Posts

|

|

Quote:

Originally Posted by Thom_44

I ran across a thread on a different forum, not a member on as mentioning the use of store bought lead bullets from a non paying vendor gets you account locked.

|

I have never heard of accounts being locked like that.

I would hope that is not the truth and I would be strongly motivated to avoid any forum that I knew was doing that.

|

|

The Following User Likes This Post:

|

|

04-02-2024, 12:47 PM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

Quote:

Originally Posted by gjgalligan

I have never heard of accounts being locked like that.

I would hope that is not the truth and I would be strongly motivated to avoid any forum that I knew was doing that.

|

I have had several accounts locked on that particular forum.

First one was asking about better ways to load oregon trails cast rifle bullets with gas check, within 1 hour account was locked for "trolling". The only thing i asked was that question.

Second one, I asked if there was a way to get better cleanliness with those bullets as the bullet length required the gas check and about 1/8" of bare lead bullet shank to be inside the case mouth to actually FIT in my chamber.

closed for "trolling"

Then the latest account was simply locked because i was asking about non paying vendor sources for polymer coated bullets, and talking about smith and wesson revolvers. That forum is die hard Ruger now for some reason.

|

04-02-2024, 10:02 PM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,490

Likes: 5,888

Liked 9,349 Times in 3,502 Posts

|

|

Quote:

Originally Posted by Thom_44

The thread was that one can apply a gas check to ANY cast bullet, regardless of if the cast bullet came from a bullet mold intended for gas checking.

|

I say only plain/flat base lead bullets. I've not had any success trying it on bevel based lead bullets.

Below is from a previous post of mine:

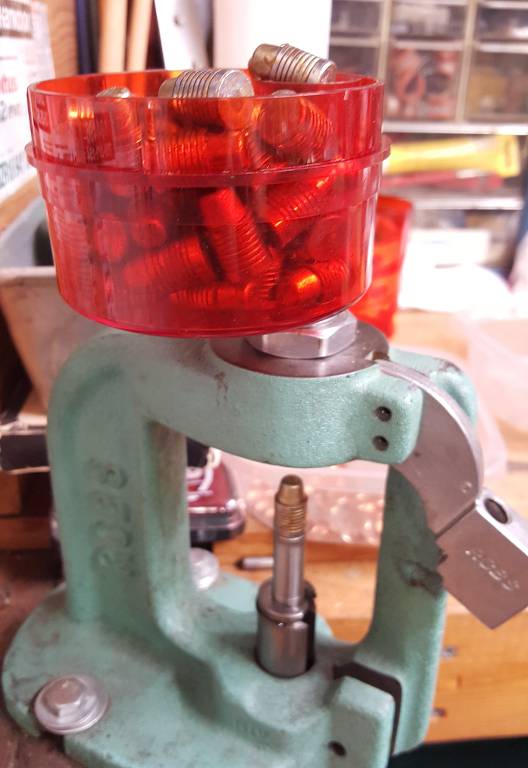

"Concerning the application of gas checks to cast leads bullets. It's correct that bullets intended to have a gas check will have the recessed base for it.

But I had always been curious as the whether you could apply a gas check to a regular flat base cast bullet & have it work.

The situation arose when I purchased some bullets from a local caster at the gun show. Most of those bullets turned out to be of poor or "questionable value" once I sat down to handload them.

Besides being unsized (too large for my needs) they frequently had wrinkles & voids. Hateing to throw them away I sat the unused ones aside until I got this idea to try.

I found a partial package of Hornady gas checks at one LGS. Another LGS had a Lee .429" Sizing (Push-Thru) Kit. Both reasonably priced for this experiment.

.

.

.

First I ran the unsized bullets thru the sizer to have a uniform diameter to work with.

.

.

.

Next I sat the sized bullet on a gas check on the kit's punch that was installed in my RCBS JR3's ram.

.

.

.

Then I pressed the bullet/gas check into the kit's sizing die until it was fully inside. Next I inserted a .427" pin gage into the top of sizing die allowing it to sit on the bullet's nose.

.

.

Lastly I gave the exposed pin gage a hard wack with my wooden mallet & then pushed the bullet the rest of the way thru the sizer with a small wooden dowel.

The experiment was a success. The gas checks were firmly seated on the base & sized correctly. Next trip to the range showed they shot great & without the leading the non-gas checked bullets gave.

Yes it was extra work & added cost to those "questionable bullets" but I got to use them up, have some fun, & was able to answer my original question - it can be done.  "

.

.

.

.

These were swaged plain/flat base lead bullets that I added gas checks to.

.

.

__________________

Waiting for the break of day

Last edited by BLUEDOT37; 04-02-2024 at 10:04 PM.

Reason: .

|

|

The Following 4 Users Like Post:

|

|

04-03-2024, 12:51 AM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

The original source i remember, did include them playing with Lee tumble lube bullets, but it was tumble lube wadcutters..

My issue is, that i am not set up for casting, and i need to purchase a metal target system before i can actually be shooting enough to cast my own bullets. And i still need to order up a work table for my darkroom first.

|

04-03-2024, 09:40 AM

|

|

Member

|

|

|

Join Date: Nov 2011

Location: Baton Rouge, La.

Posts: 6,874

Likes: 7,481

Liked 8,138 Times in 3,679 Posts

|

|

Easy Answer -

Standard gas checks will not work on plain based cast bullets as they are too thick .

But there is a special much thinner gas check sold by Sage's Outdoors

( Gas Checks - Sage's Outdoors ) called "Plain Base Gas Check " and these do work very well .

But ... you have to have a tool to press the Plain Base Gas Check onto the base and size it flush ... Lee sells a little sizer you can use in a press and I'm sure Sage's sells it / or his own check applying / bullet sizer .

Be sure and get the correct diameter sizer with your tool for the size you want your bullet diameter .

And don't forget bullet lube ... you may want to tumble lube them as a gas check doesn't take the place of bullet lube it just helps it !

No bevel based bullets ...GC's want flat or nearly flat .

Good Luck

Gary

__________________

Certified Cajun

NRA Member

Last edited by gwpercle; 04-03-2024 at 09:46 AM.

|

|

The Following User Likes This Post:

|

|

04-03-2024, 10:10 AM

|

|

US Veteran

|

|

|

Join Date: Nov 2009

Location: Michigan Western UP

Posts: 12,986

Likes: 3,056

Liked 14,412 Times in 5,485 Posts

|

|

The first question I have to ask is what speed are you shooting? The second question is what revolver are you using? The rifling in various guns are not al the same and some are made with fast twist rifling designed to shoot at specific speeds. Leading does not have anything to do with gas checks when using lead because too much velocity and fast rifling will strip lead off the bullet. Gas checks are designed to prevent the ignition gases from melting lead at the rear of the bullet, which is another way to lead barrels.

The answer is you will be fine shooting standard lead bullets at the right velocity. Since you stated that you get leading when you go with hotter loads, slow down until you no longer get leading.

Easiest ways to eliminate leading is to, first, match the diameter of your bullet with the rifling as detailed above. Too large a bullet will guarantee leading. Second is to check velocities. I had a friend that loaded 38 Special and did not own a chronometer, which I feel is absolutely essential for a reloader. I took mine out to find he was shooting 38 Special at 1250 fps in a standard M&P!! He adjusted his loads and ended leading problems, while saving his revolver from over-pressure loads. Keep loads down to standard velocities. If you want to hot-rod your loads, buy a revolver that is designed for the higher speeds, or shoot jacketed bullets.

Lastly, get a Lee bullet sizer to guarantee your bullets will be all the same size. I cast my own and am never happy with the tolerances in casting. Measuring some, I see .005" difference, way too much variation. Sizer is super-easy to use and worth the effort. I size first and then use Alox before I load lead bullets. Results are much lower SD, no leading, and better accuracy - what more could one ask for??

BTW, Missouri bullets are my go-to for cast lead.

__________________

Gary

SWCA 2515

Last edited by glowe; 04-03-2024 at 10:14 AM.

|

|

The Following User Likes This Post:

|

|

04-03-2024, 10:50 AM

|

|

Member

|

|

|

Join Date: Aug 2014

Posts: 100

Likes: 3

Liked 78 Times in 31 Posts

|

|

I use coated bullets at moderate velocities in 9mm, 38 41m and 45acp with little leading. There will always be a little, but not so much that the bore will not clean easily.

Check the page at this link for what I mean.

Missouri Bullet Company

|

|

The Following 2 Users Like Post:

|

|

04-03-2024, 11:40 AM

|

|

US Veteran

|

|

|

Join Date: Nov 2009

Location: Michigan Western UP

Posts: 12,986

Likes: 3,056

Liked 14,412 Times in 5,485 Posts

|

|

Let me add an attachment that was originally from S&W back in the pre-WWII era. Always thought of it as the standard that the revolvers were designed to shoot and I seldom exceed from those bullet weights and velocities.

__________________

Gary

SWCA 2515

|

|

The Following 2 Users Like Post:

|

|

04-03-2024, 11:43 AM

|

|

Member

|

|

|

Join Date: Oct 2019

Location: Georgia

Posts: 2,156

Likes: 4,478

Liked 2,020 Times in 966 Posts

|

|

Quote:

Originally Posted by richrd

I use coated bullets at moderate velocities in 9mm, 38 41m and 45acp with little leading. There will always be a little, but not so much that the bore will not clean easily.

Check the page at this link for what I mean.

Missouri Bullet Company |

I powder coat my own boolits. But I have also used Missouri, my brother ordered some 230 Hi-Tek coated and they have been excellent in the 45 ACP using N310 powder. He told me they were more accurate in his 1911 6" than any factory loads he has bought.

Rosewood

|

04-03-2024, 05:23 PM

|

|

Member

|

|

|

Join Date: Sep 2011

Location: Puget Sound

Posts: 2,940

Likes: 8,905

Liked 5,324 Times in 1,878 Posts

|

|

Quote:

Originally Posted by Thom_44

I have had several accounts locked on that particular forum.

First one was asking about better ways to load oregon trails cast rifle bullets with gas check, within 1 hour account was locked for "trolling". The only thing i asked was that question.

Second one, I asked if there was a way to get better cleanliness with those bullets as the bullet length required the gas check and about 1/8" of bare lead bullet shank to be inside the case mouth to actually FIT in my chamber.

closed for "trolling"

Then the latest account was simply locked because i was asking about non paying vendor sources for polymer coated bullets, and talking about smith and wesson revolvers. That forum is die hard Ruger now for some reason.

|

Would you be willing to name the forums? If I happen to be a member, I'd like to know so I can hold my tongue and not get banished.

|

04-03-2024, 05:49 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Posts: 3,260

Likes: 22

Liked 5,581 Times in 1,955 Posts

|

|

My first experience with lead bullets was 53 years ago. It was with Speer 148 Wadcutters in a 38 spl. OMG leading like crazy. That's what convinced me to cast my own.

I started with a Lee mold, fed with lead, linotype and bar solder, formulated to Lyman #2. My Dad was a printer and my factory replaced all the lead pipe. Thus, my raw materials were free. When those sources ran out some 20 years later I switched to 100% wheel weights. My hardness numbers over the years were in the 12-15 range.

Initially I lubed with beeswax, but then I switched to Lee liquid alox via tumble lube.

In the past 52 years (after store bought) I have not detected a single leaded barrel, comprising .38, .357, .41, .45, etc.

Just for convenience I experimented with store bought coated bullets from 2 different manufacturers. My objective was to TRY before I actually bought the coating, toaster oven, etc. The test was with .358 SWC exactly like I make myself.

Pfffft with that. My Lee 158's outperformed the coated bullets. I never switched to powder coating my own.

Short story long....if I could not cast my own I would buy powder coated. The 2 I tried were Summit City and Hoosier. They performed fine, although not as good as mine.

|

04-04-2024, 01:22 AM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

Quote:

Originally Posted by glowe

The first question I have to ask is what speed are you shooting? The second question is what revolver are you using? The rifling in various guns are not al the same and some are made with fast twist rifling designed to shoot at specific speeds. Leading does not have anything to do with gas checks when using lead because too much velocity and fast rifling will strip lead off the bullet. Gas checks are designed to prevent the ignition gases from melting lead at the rear of the bullet, which is another way to lead barrels.

The answer is you will be fine shooting standard lead bullets at the right velocity. Since you stated that you get leading when you go with hotter loads, slow down until you no longer get leading.

Easiest ways to eliminate leading is to, first, match the diameter of your bullet with the rifling as detailed above. Too large a bullet will guarantee leading. Second is to check velocities. I had a friend that loaded 38 Special and did not own a chronometer, which I feel is absolutely essential for a reloader. I took mine out to find he was shooting 38 Special at 1250 fps in a standard M&P!! He adjusted his loads and ended leading problems, while saving his revolver from over-pressure loads. Keep loads down to standard velocities. If you want to hot-rod your loads, buy a revolver that is designed for the higher speeds, or shoot jacketed bullets.

Lastly, get a Lee bullet sizer to guarantee your bullets will be all the same size. I cast my own and am never happy with the tolerances in casting. Measuring some, I see .005" difference, way too much variation. Sizer is super-easy to use and worth the effort. I size first and then use Alox before I load lead bullets. Results are much lower SD, no leading, and better accuracy - what more could one ask for??

BTW, Missouri bullets are my go-to for cast lead. |

Well i have no idea on actual velocity I am able to achieve. I do know that the 18 grains/2400 left a good heavy ridge of lead residue right at the start of my rifling.

Have just purchased 50 lb of lead ingots on amazon, oddly shipping from Roto Metals, but at far lower cost.

Just need to figure out melting pot, doubt melting in a spoon over a candle is gonna work like in some colonial era set movies

|

|

The Following User Likes This Post:

|

|

04-04-2024, 07:16 AM

|

|

Member

|

|

|

Join Date: Feb 2007

Location: Ohio

Posts: 1,468

Likes: 181

Liked 1,661 Times in 691 Posts

|

|

IMHO:

You need to up that 2400 load, you +/- 1gr below minimum trying to push a fairly hard bullet that has a hard lube. Try bumping that load up to 19/20gr. (Elmer used 22gr with a +/- 10bhn bullet)

2400 typically doesn't reach full pressure until it's around 2 inches into the barrel. Until then 2400 relies on the softness of the bullets alloy to obturate in the bbl. Along with the bullet lube to act like a gasket (I've always referred to bullet lube as a gasket).

You're 7.0gr load of reddot in +/- 27,000psi.

You're 18gr load of 2400 is +/- 18,000psi

Might not be enough pressure to expand/compress that bullets hardness along with the hard lube.

|

|

The Following User Likes This Post:

|

|

04-04-2024, 12:33 PM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

Quote:

Originally Posted by Forrest r

IMHO:

You need to up that 2400 load, you +/- 1gr below minimum trying to push a fairly hard bullet that has a hard lube. Try bumping that load up to 19/20gr. (Elmer used 22gr with a +/- 10bhn bullet)

2400 typically doesn't reach full pressure until it's around 2 inches into the barrel. Until then 2400 relies on the softness of the bullets alloy to obturate in the bbl. Along with the bullet lube to act like a gasket (I've always referred to bullet lube as a gasket).

You're 7.0gr load of reddot in +/- 27,000psi.

You're 18gr load of 2400 is +/- 18,000psi

Might not be enough pressure to expand/compress that bullets hardness along with the hard lube.

|

Alliant 1995 says 240 lead with max 8.8 grains red dot is 39,,5000 PSI

Alliant 2005 says 8.8 grains is 34,900 PSI

|

04-04-2024, 04:26 PM

|

|

Member

|

|

|

Join Date: Aug 2023

Location: The Dells, WI

Posts: 153

Likes: 149

Liked 196 Times in 86 Posts

|

|

You sure those pressures are both stated in "PSI" ... ?

|

04-05-2024, 03:02 AM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

Quote:

Originally Posted by taz666

You sure those pressures are both stated in "PSI" ... ?

|

Yeppers, column title is pressure PSI ANY load measured in cup has CUP directly in the same box with the chamber pressure.

Looked up their alliant load data for 357 magnum WADCUTTERS

I really really really ******* hope they mean HBWC for "target wadcutter" and DEWC for the row titled with just "wadcutter"

5.6" barrel length listed

Bullseye

148 LWC (TARGET) 2.8gr 780 fps 10,000 PSI

148 LWC 5.7 gr 1,475 fps 34,000 PSI

Red Dot

148 LWC (target) 2.7 gr 775 fps 10,000 PSI

148 LWC 4.6gr 1,300 fps 33,600 PSI

2400

148 LWC 12.2 gr 1,675 fps 33,800 PSI

Ironically the (target) data is the same as 38 special data for same powders. Really really makes the new style barrel in the K frame look like a goooood idea

|

04-05-2024, 03:48 PM

|

|

Member

|

|

|

Join Date: Mar 2023

Posts: 830

Likes: 1,088

Liked 908 Times in 450 Posts

|

|

Quote:

Originally Posted by GypsmJim

My first experience with lead bullets was 53 years ago. It was with Speer 148 Wadcutters in a 38 spl. OMG leading like crazy. That's what convinced me to cast my own.

|

I started with Speer 148 HBWC and 2.8 grains of Bullseye back then too. I shot PPC Competition and I never had a problem of leading.

Other cops I knew who were reloaders would invert the Speer HBWC put a hefty load of powder in and then was upset with leading.

|

04-05-2024, 03:54 PM

|

|

Member

|

|

|

Join Date: Mar 2023

Posts: 830

Likes: 1,088

Liked 908 Times in 450 Posts

|

|

Quote:

Originally Posted by Thom_44

My gun prefers 6 grains red dot, and matts .430 diam 240 swc.

I still get leading when i go with hotter loads ...

|

240 LSWC and 44 Mag brass you are max with 6.5 grains of Red Dot with 44 Special brass the max with Red Dot is 5.0 grains. Speer Manual #12.

|

04-05-2024, 04:09 PM

|

|

Member

|

|

|

Join Date: Mar 2023

Posts: 830

Likes: 1,088

Liked 908 Times in 450 Posts

|

|

Quote:

Originally Posted by Thom_44

Alliant 1995 says 240 lead with max 8.8 grains red dot is 39,,5000 PSI

Alliant 2005 says 8.8 grains is 34,900 PSI

|

Alliant 2018 says 6.5 grains of Red Dot is max in 44 Mag brass.

|

04-05-2024, 04:29 PM

|

|

Member

|

|

|

Join Date: May 2011

Location: USA

Posts: 280

Likes: 5

Liked 249 Times in 116 Posts

|

|

I have tried the Sage's plain base checks. They are aluminum, very thin, and have teeth on the sides, to bite into the bullets. They install best on softer bullets. Of course, you need a press, and the proper size die to crimp them.

I bought 500 just for the heck of it, and tried them on some 40 S&W bullets, that were very soft. They worked just fine. I never bought any more of them, as they were just an experiment for me.

|

04-05-2024, 04:30 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Posts: 3,260

Likes: 22

Liked 5,581 Times in 1,955 Posts

|

|

Quote:

Originally Posted by SGT ROCK 11B

I started with Speer 148 HBWC and 2.8 grains of Bullseye back then too. I shot PPC Competition and I never had a problem of leading.

Other cops I knew who were reloaders would invert the Speer HBWC put a hefty load of powder in and then was upset with leading.

|

Same for me, with 2.7 BE. The gun was a brand new Ruger Security Six. I ran them right side up.

I can't explain the difference.

|

04-05-2024, 07:56 PM

|

|

Member

|

|

|

Join Date: Feb 2007

Location: Ohio

Posts: 1,468

Likes: 181

Liked 1,661 Times in 691 Posts

|

|

Quote:

Originally Posted by Thom_44

Alliant 1995 says 240 lead with max 8.8 grains red dot is 39,,5000 PSI

Alliant 2005 says 8.8 grains is 34,900 PSI

|

Thank you, what does that have to do with 7.0gr of reddot making 27,000psi????

Perhaps you should be looking at that sssssuuuuuuuppppppeeeeeeeerrrr hhhhhhhhooooooooottttttt load of 2400!!!!!!!

Heck, it's only 1 1/2gr below the "starting load" for that 240gr/2400 combo.

Last I knowd, hard bullets and lite loads caused leading.

Any ideas what alliant said about an 18gr load seeing how you bothered to look up the reddot load???

|

04-06-2024, 02:11 AM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

Quote:

Originally Posted by SGT ROCK 11B

Alliant 2018 says 6.5 grains of Red Dot is max in 44 Mag brass.

|

And you need to understand, as many others do.

1. call Alliant up and verify for yourself

The TYPE of bullet.

2. They have changed since the 1995 manual to using soft swaged bullets for everything.

3. When i emailed them the other year, like many others, i was told they still stand by the data in that manual

|

|

The Following User Likes This Post:

|

|

04-06-2024, 12:33 PM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

I have my 50 pounds of lead, 4-6 days before it was supposed to have arrived. It came by mail.

Im really surprised i didnt come home and find the mail carrier crushed to death under it. I can barely heft that bugger up

|

04-06-2024, 06:35 PM

|

|

Member

|

|

|

Join Date: Mar 2023

Posts: 830

Likes: 1,088

Liked 908 Times in 450 Posts

|

|

I prefer Superior Cast Bullets from X-Treme Bullets (especially their .44 and .45 caliber bullets)

All of our Superior Cast Bullets (SCB) are 'hard cast' using a tough, time-proven alloy. Our hard alloy combined with the most efficient bullet lube available enhances accuracy and minimizes barrel fouling. Literally hundreds of X-Treme SCB bullets can be fired without any decline in accuracy and without cleaning your barrel. We pride ourselves on the extremely consistent weight tolerances we're able to maintain -- a critical key to accuracy. We offer the most popular bullet shapes for both target shooters and hunters.

Hard Cast Lead Bullets

|

04-06-2024, 06:42 PM

|

|

Member

|

|

|

Join Date: Mar 2023

Posts: 830

Likes: 1,088

Liked 908 Times in 450 Posts

|

|

Quote:

Originally Posted by Thom_44

The thread was that one can apply a gas check ...

|

I have only used Gas Checks on lead bullets for my Winchester Model 94 in .30/30.

|

04-06-2024, 07:34 PM

|

|

Member

|

|

|

Join Date: Apr 2024

Posts: 148

Likes: 2

Liked 81 Times in 53 Posts

|

|

Today I had time to finally shoot my unique loads.

matts 240 swc, 8.5 grains Unique. Due to the target issue i had, having to reset it after every shot, i managed two cylinders in 3" group at 10 yards.

Went to 25 yards, and double action was not pleasing. Single action cylinder was not pleasing either.

Used 10 grain load, 1 cylinder at 25 yards not pleased with how it grouped. When to 10 yards, better accuracy.

Overall 30 rounds fired, cant see leading in the barrel. The start of the rifling is as clean as before i started shooting. A light smear of lead on the forcing cone, and in the chambers, and powder stains on cylinder. Even had a LUBE RING on the muzzle. VERY light and only in the muzzle crown.

|

04-06-2024, 07:54 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Posts: 3,260

Likes: 22

Liked 5,581 Times in 1,955 Posts

|

|

Quote:

Originally Posted by Forrest r

Last I knowd, hard bullets and lite loads caused leading.

|

Absotuely tru. The problem is too many people don't understand that.

* Lead too soft...lead too hard.

* Boolets too small....barrel too big

* too much powder...too little powder

|

04-06-2024, 07:59 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Posts: 3,260

Likes: 22

Liked 5,581 Times in 1,955 Posts

|

|

Quote:

Originally Posted by Thom_44

I have my 50 pounds of lead, 4-6 days before it was supposed to have arrived. It came by mail.

Im really surprised i didnt come home and find the mail carrier crushed to death under it. I can barely heft that bugger up

|

I got a bucket full of wheel weights at local gas stations by giving the guys a free pizza. When zinc became the thing in my state I bought a whole bunch of 50# boxes on e-bay for cheap, with the idea of gathering a lifetime supply. I DID, in fact.

I have rural delivery with the mailbox at the curb. My mailman used to back up the driveway so he didn't have to carry the boxes so far. I apologized to him once and he said no problem, it was his job.

|

|

Posting Rules

Posting Rules

|

|

|

|

|