I recently found this at auction. The seller poorly listed it and did not know the caliber. I suspected it was a target tool so I bid on it and got it for a song.

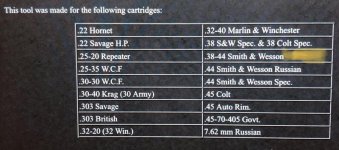

The wife was wondering why I jumped up and down when I opened the package. The 38-44 Target tool is pretty rare. How rare? This is the first time I’ve had the opportunity to get one.

Cleaned it up and it has perfect deep stamp markings. I’m happy with the turn out.

What I’m wondering is if this tool is right? I have seen a 32-44 T without a bullet mold but never a 38-44T.

It doesn’t look to me like the mold block was removed but I’m not 100% on this one.

Anyone have one of these without the bullet mold?

Murph

The wife was wondering why I jumped up and down when I opened the package. The 38-44 Target tool is pretty rare. How rare? This is the first time I’ve had the opportunity to get one.

Cleaned it up and it has perfect deep stamp markings. I’m happy with the turn out.

What I’m wondering is if this tool is right? I have seen a 32-44 T without a bullet mold but never a 38-44T.

It doesn’t look to me like the mold block was removed but I’m not 100% on this one.

Anyone have one of these without the bullet mold?

Murph