Factory vs Agency

Jim,

That's great info!

I agree with most of what you posted.

We have to consider the many agency offices around the country that represented Ideal, Marlin, and later Lyman as legitimate suppliers of Ideal tools and as a 100% legitimate source of Marks tool. They did not have the benefit of raw production like the factory but would have had a fully qualified machinist on site.

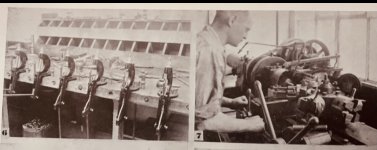

See photo 1&2 of the on site shop of Pacific gunsight circa 1925 in San Francisco. Able to fabricate any die in specified caliber the customer requested.

See photo 3&4

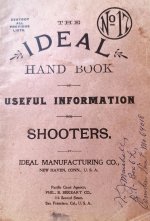

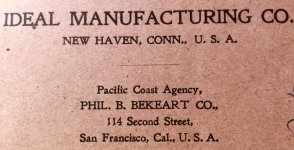

This original authentic and rare circa 1906 Ideal San Francisco agency marked reloading manual not only proves their existence but the exact address in San Francisco just prior to the 1906 earthquake and fire. The agency marking is part of the original cover print from Ideal. It was not stamped by the agency after receipt from Ideal.

You will also note the name listed is a well known dealer in firearms during that early period. His name shows up often in my research of early Target weapons and special order items that are also found having non factory characteristics. Often also from factory shipping ledgers shipped directly to him by name.

The loading die found on Marks tool stamped 122 must have purposely been machined to load the 32-44 case. A 32 Auto or 32 S&W die is too small in diameter to load the 32-44 case with .323 bullet diameter. Simply said the 32-44 case won't fit in the 122 die without machining.

This supports professional alteration or machining of the die to conform to loading the special 32-44 Target round. This alteration was not performed by Bubba using a drill press. It had to be completed by a competent machinist. Also, Ideal offered two separate plungers. One for the conical and a separate plunger for the ball or gallery round. One plunger did not perform both tasks.

In my opinion remote agency offices would have to often use what parts they had on hand at the time to manufacture what the customer wanted. With a machinist on site the task would be quickly accomplished. However, to a collector reading known charts and numbers 100+ years later, something will always be amiss. Even though the charts are often found altered by Ideal from year to year.

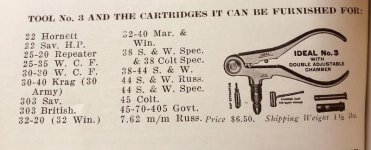

See last photo of an earlier chart that lists a different die number for the 32 S&W and "Special" for the 32 Auto as compared to my previous chart that shows die 122 for all 3 calibers.

So it's not an exact science from my researched standpoint when it comes to the final product it ultimately depends on where it was assembled and at what time in history.

Murph

Jim,

That's great info!

I agree with most of what you posted.

We have to consider the many agency offices around the country that represented Ideal, Marlin, and later Lyman as legitimate suppliers of Ideal tools and as a 100% legitimate source of Marks tool. They did not have the benefit of raw production like the factory but would have had a fully qualified machinist on site.

See photo 1&2 of the on site shop of Pacific gunsight circa 1925 in San Francisco. Able to fabricate any die in specified caliber the customer requested.

See photo 3&4

This original authentic and rare circa 1906 Ideal San Francisco agency marked reloading manual not only proves their existence but the exact address in San Francisco just prior to the 1906 earthquake and fire. The agency marking is part of the original cover print from Ideal. It was not stamped by the agency after receipt from Ideal.

You will also note the name listed is a well known dealer in firearms during that early period. His name shows up often in my research of early Target weapons and special order items that are also found having non factory characteristics. Often also from factory shipping ledgers shipped directly to him by name.

The loading die found on Marks tool stamped 122 must have purposely been machined to load the 32-44 case. A 32 Auto or 32 S&W die is too small in diameter to load the 32-44 case with .323 bullet diameter. Simply said the 32-44 case won't fit in the 122 die without machining.

This supports professional alteration or machining of the die to conform to loading the special 32-44 Target round. This alteration was not performed by Bubba using a drill press. It had to be completed by a competent machinist. Also, Ideal offered two separate plungers. One for the conical and a separate plunger for the ball or gallery round. One plunger did not perform both tasks.

In my opinion remote agency offices would have to often use what parts they had on hand at the time to manufacture what the customer wanted. With a machinist on site the task would be quickly accomplished. However, to a collector reading known charts and numbers 100+ years later, something will always be amiss. Even though the charts are often found altered by Ideal from year to year.

See last photo of an earlier chart that lists a different die number for the 32 S&W and "Special" for the 32 Auto as compared to my previous chart that shows die 122 for all 3 calibers.

So it's not an exact science from my researched standpoint when it comes to the final product it ultimately depends on where it was assembled and at what time in history.

Murph

Attachments

Last edited: