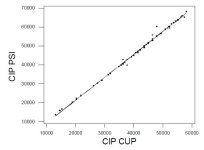

Generally, there is no good way to make a comparison between CUP and actual piezo gauge chamber pressure measurements, because CUP is in fact not a pressure measurement at all. Rather it is something analogous to a pressure measurement, namely the amount a copper pellet is crushed under the pressure of firing. It should be considered only as an analog indicator of pressure, not a pressure measurement. It is a very old method, dating from the days long before anything electronic existed. The general assumption is that actual peak chamber pressure (in PSI), as measured by a piezo gauge according to SAAMI methods will be up to 20% greater than a copper crusher determination (in CUP) under the same conditions. In effect, the CUP is an indicator of a sort-of "average" chamber pressure, as it has a much longer response time, vs. the piezo gauge's near-instantaneous (microseconds) response time. The chart provided above has the axes labeled as CIP. CIP is a European standards organization and uses a pressure test method which is somewhat different from the SAAMI method, although both use piezo gauges. I know of no ammunition manufacturers which today continue to use the copper crusher method, as the piezo gauge method, in widespread use since about 1970, is much faster, simpler, and far more precise than the copper crusher method. It also allows measurement of pressure vs. time, which the copper crusher method cannot. I have been in about every manufacturer's ballistics lab, and several military labs, and there are no copper crusher barrels in use. However, SAAMI still recognizes the use of both methods at present.