renconchem

New member

- Joined

- Aug 6, 2013

- Messages

- 3

- Reaction score

- 2

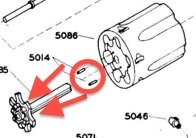

I have a Nickel Plated Model 10-6 .38 Spec I inherited from my grandfather. Recently, I pulled it out of the safe after having cleaned it and tried to open the cylinder and had to use a significant amout of force to get it open. First thing I checked to see if the extractor rod was tight and it was. Then I spun the cylinder to check if it was bent which it was not. I also checked the locking bolt to see if it was jammed up but it was moving freely. I also can depress the center pin easily enough without it getting stuck, but just to be though I unscrewed the extractor rod to see if it was dirty and added a drop of oil however the cylinder is still getting stuck. Short of taking it to a gun smith anyone have some idea what is going on?