Hello guys,

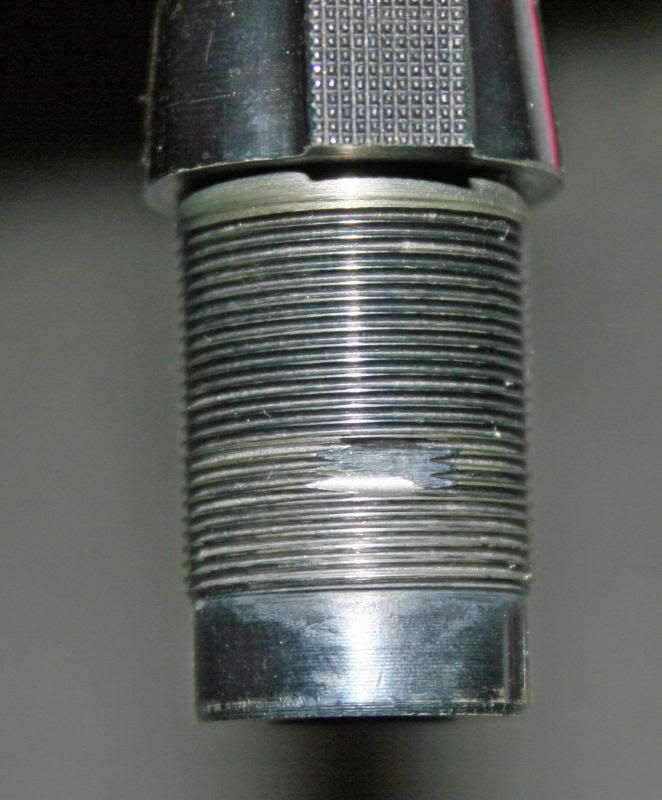

I had a great shooting session with my 500 magnum 8 3/8 revolver using mild reloads . When cleaning I noticed a ring on the inside surface of the barrel. Can't get rid of it. Any ideas. Also, took the gun shooting again and change in the performance.

Thanks.

I had a great shooting session with my 500 magnum 8 3/8 revolver using mild reloads . When cleaning I noticed a ring on the inside surface of the barrel. Can't get rid of it. Any ideas. Also, took the gun shooting again and change in the performance.

Thanks.