|

|

|

01-13-2015, 11:19 PM

|

|

Member

|

|

|

Join Date: Mar 2009

Location: mid Missouri

Posts: 1,871

Likes: 9,407

Liked 2,561 Times in 1,011 Posts

|

|

is it possible to repair a revolver with a "sprung crane"?

is it possible to repair a revolver with a "sprung crane"?

Will even the S&W factory be able to repair one, or is a matter of too much cost to get it done? Years ago, I'd see some nice revolvers at gun shows with badly sprung cranes for bargain prices & had always passed them by.

my late father in law had purchased a used 586 that had a sprung crane when he got it, he rarely shot it & as far as I know made no effort to having it repaired.

thanks in advance for an answer, I reviewed all the old pages & FAQ's posted here & saw nothing discussing this.

__________________

be safe,enjoylife,journey well

|

01-13-2015, 11:31 PM

|

|

Member

|

|

|

Join Date: Nov 2007

Location: Atlanta, GA

Posts: 8,196

Likes: 4,320

Liked 12,478 Times in 3,877 Posts

|

|

If not severely damaged, cranes can be straightened. I own a S&W 63 that was thrown from a moving vehicle. The factory repaired the gun, which included straightening the crane.

|

01-13-2015, 11:32 PM

|

|

US Veteran

|

|

|

Join Date: Oct 2013

Location: Central Montana

Posts: 14,840

Likes: 14,609

Liked 43,941 Times in 11,024 Posts

|

|

Although I myself have never done so it should be possiple to "form"the crane back to its original position. One would need to make some jigs to prevent damage to the tube. I would use an arbor press myself. You could also get another crane.

|

|

The Following User Likes This Post:

|

|

01-13-2015, 11:38 PM

|

|

Member

|

|

|

Join Date: Sep 2004

Location: Wyoming

Posts: 3,259

Likes: 1,224

Liked 2,527 Times in 1,044 Posts

|

|

I would sure think the factory could and would. Many years ago I did it with a beater old 1917 Colt. It involved either chucking the crane arbor(s) in a leather jaw vise and whacking things in the preferred direction with a wood mallet; or whacking on the rear of the cylinder with the crane and cylinder out and cradled in the palm of the off hand to persuade it to go where you wanted it to. The results were pretty good, but on the other hand there wasn't much to lose, either.

I suspect the factory does about the same thing. The owner isn't there to watch the process, and that would be a good thing.

|

|

The Following User Likes This Post:

|

|

01-13-2015, 11:44 PM

|

|

Member

|

|

|

Join Date: Mar 2009

Location: mid Missouri

Posts: 1,871

Likes: 9,407

Liked 2,561 Times in 1,011 Posts

|

|

thanks for the answers, I'm rather too timid to try whacking on a pretty revolver if S&W can reasonably repair it, rather than to have a revolver with 1 repair needed, to having one with several Bubbaed gunsmith "fixes" that needed to be addressed by the factory at the same time.

Any ideas on what the factory charges?

__________________

be safe,enjoylife,journey well

|

01-14-2015, 12:36 AM

|

|

Member

|

|

|

Join Date: Feb 2010

Location: Kansas City area

Posts: 1,052

Likes: 172

Liked 539 Times in 182 Posts

|

|

Many years ago I watched Ron Powers beat a yoke back into a perfect fit with a large lead bar. Never seen that done before or since.

__________________

Dick

|

|

The Following User Likes This Post:

|

|

01-14-2015, 07:26 AM

|

|

Member

|

|

|

Join Date: Mar 2012

Posts: 5,930

Likes: 4,044

Liked 6,123 Times in 2,619 Posts

|

|

It's perfectly possible and one of the simpler fixes. S&W call cranes yokes, by the way.

A Kuhnhausen manual, a babbit (lead) bar, a nylon wedge, a nylon hammer and a yoke alignment tool are all that's needed; not very expensive at Brownells or other retailers.

S&W can definitely do it, as can any qualified revolversmith and most mechanically inclined do-it-yourselfers who get the right tools and follow Kuhnhausen's instructions.

One of the cheaper fixes if you pay to have it done, I'd think, based on the quickness and simplicity of the work usually involved; lists in the $30 to $50 range with most well-known gunsmiths with websites.

|

|

The Following 2 Users Like Post:

|

|

01-14-2015, 07:59 AM

|

|

US Veteran

|

|

|

Join Date: Dec 2008

Location: New England

Posts: 4,173

Likes: 3,543

Liked 4,000 Times in 1,628 Posts

|

|

IT CAN CERTAINLY BE REPAIRED, BUT I WOULD NOT DO IT MYSELF. WHILE THERE ARE PROBABLY MANY QUALIFIED 'SMITHS THAT COULD DO IT, I WOULD SUGGEST THAT YOU SEND IT BACK TO S&W FOR THE REPAIR. THIS WAY, YOU WILL HAVE NO PROBLEMS WITH A FAULTY REPAIR DOWN THE ROAD. JMHO………...

__________________

'Nam 1968-69.DAV,VFW,NRA Inst.

|

|

The Following 4 Users Like Post:

|

|

01-14-2015, 01:20 PM

|

|

Member

|

|

|

Join Date: Jul 2008

Location: Las Vegas, NV

Posts: 3,419

Likes: 5,932

Liked 5,275 Times in 1,733 Posts

|

|

As mentioned above; two tools, a little training and your yoke will be as good as new. A trained S&W Armorer is not completely tooled without a lead babbit bar. I had a M 10 brought to me one time that someone had tried to remove the barrel by putting a lever thru the cylinder opening and twisting. The frame was torqued by about 1/4". I got out my measuring tools, my bronze jaws for the vise and my babbit bar. About 30 minutes later the frame was back into shape and was passing the inspections. BTW, I did not let the owner watch this exercise. I told him it was like watching sausage being made. It's best that you don't. :-)

................... Big Cholla

|

|

The Following 5 Users Like Post:

|

|

01-14-2015, 01:34 PM

|

|

Member

|

|

|

Join Date: Mar 2009

Location: mid Missouri

Posts: 1,871

Likes: 9,407

Liked 2,561 Times in 1,011 Posts

|

|

Thanks for the advice guys, I'd rather pay S&W the $30.00 to $50.00 needed for a first class factory repair than to try it myself.

__________________

be safe,enjoylife,journey well

|

|

The Following 2 Users Like Post:

|

|

01-14-2015, 01:39 PM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: New York State

Posts: 6,572

Likes: 23,601

Liked 31,523 Times in 5,696 Posts

|

|

Quote:

Originally Posted by da gimp

Thanks for the advice guys, I'd rather pay S&W the $30.00 to $50.00 needed for a first class factory repair than to try it myself.

|

A man after my own heart. I just want to enjoy my S&W's, not fix them.

Sent from my iPhone using Tapatalk

|

|

The Following User Likes This Post:

|

|

01-14-2015, 02:43 PM

|

|

Member

|

|

|

Join Date: Mar 2012

Posts: 5,930

Likes: 4,044

Liked 6,123 Times in 2,619 Posts

|

|

Quote:

Originally Posted by da gimp

Thanks for the advice guys, I'd rather pay S&W the $30.00 to $50.00 needed for a first class factory repair than to try it myself.

|

If there's a good gunsmith, trained on S&W revolvers, within reasonable driving distance, consider that option, too; you'll save on shipping and likely have a faster turnaround. It's not a fix that requires the factory.

However, if you have several things in store for the revolver, a factory trip might be in order -- but just to straighten the yoke you'll pay more to send it than to fix it.

|

01-14-2015, 07:24 PM

|

|

Member

|

|

|

Join Date: Nov 2014

Posts: 155

Likes: 1

Liked 163 Times in 58 Posts

|

|

I've heard people say...there's no advantage in forged steel over cast steel.

Oh yeah? Here's one. If it gets bent, you can bend it back.

|

01-14-2015, 09:05 PM

|

|

Member

|

|

|

Join Date: May 2001

Posts: 1,473

Likes: 0

Liked 1,052 Times in 453 Posts

|

|

Quote:

Originally Posted by BigChief52

I've heard people say...there's no advantage in forged steel over cast steel.

Oh yeah? Here's one. If it gets bent, you can bend it back.

|

You can also bend cast steel.

This is what Ruger does to repair sprung Ruger revolver cranes.

|

|

The Following User Likes This Post:

|

|

01-14-2015, 09:11 PM

|

|

Member

|

|

|

Join Date: Nov 2007

Location: Atlanta, GA

Posts: 8,196

Likes: 4,320

Liked 12,478 Times in 3,877 Posts

|

|

My S&W 63 had gouges full of asphalt on the frame and barrel and burrs along the trigger guard, the ejector rod was bent, the locating tabs on the hand were sheared off, the gun would not cock, the cylinder would not open. It was cosmetically and mechanically repaired, with new ejector rod, hand and some other part, plus shipping back to me, cost me right at $125.00 and took right at six weeks.

|

01-14-2015, 10:24 PM

|

|

US Veteran

|

|

|

Join Date: Jan 2007

Location: Sandy Utah

Posts: 9,859

Likes: 2,010

Liked 11,856 Times in 4,467 Posts

|

|

Quote:

Originally Posted by BigChief52

I've heard people say...there's no advantage in forged steel over cast steel.

Oh yeah? Here's one. If it gets bent, you can bend it back.

|

FWIW, ALL steel is cast! The cast billet is then processed by rolling, drawing, forging, piercing, turning, etc. Cast STEEL is not brittle as cast Iron or Aluminum usually are. Casting the steel directly in the form of a gun frame, slide or other part does not change this.

__________________

Gunsmithing since 1961

|

01-14-2015, 11:27 PM

|

|

Member

|

|

|

Join Date: Mar 2012

Posts: 5,930

Likes: 4,044

Liked 6,123 Times in 2,619 Posts

|

|

Quote:

Originally Posted by ColbyBruce

My S&W 63 had gouges full of asphalt on the frame and barrel and burrs along the trigger guard, the ejector rod was bent, the locating tabs on the hand were sheared off, the gun would not cock, the cylinder would not open...

|

Must've been a hell of a range session...

|

|

The Following User Likes This Post:

|

|

01-15-2015, 07:05 AM

|

|

US Veteran

|

|

|

Join Date: Dec 2008

Location: New England

Posts: 4,173

Likes: 3,543

Liked 4,000 Times in 1,628 Posts

|

|

Quote:

Originally Posted by ColbyBruce

My S&W 63 had gouges full of asphalt on the frame and barrel and burrs along the trigger guard, the ejector rod was bent, the locating tabs on the hand were sheared off, the gun would not cock, the cylinder would not open. It was cosmetically and mechanically repaired, with new ejector rod, hand and some other part, plus shipping back to me, cost me right at $125.00 and took right at six weeks.

|

WOW, IT SOUNDS LIKE IT WAS RIDING IN THE HOLSTER OF A BIKER WHO TOOK A SPILL. PRETTY UGLY. I DON'T THINK YOU COULD ASK FOR BETTER SERVICE AT A REASONABLE PRICE, THAN YOU GOT FROM S&W ON THAT JOB. IN GENERAL, I HAVE BEEN PLEASED BY MY EXPERIENCE WITH THE S&W SERVICE DEPARTMENT. I THINK THAT IT'S WORTH A LITTTLE EXTRA MONEY SOMETIMES, TO KNOW THAT THE JOB WILL BE DONE RIGHT……..

__________________

'Nam 1968-69.DAV,VFW,NRA Inst.

|

01-15-2015, 07:58 AM

|

|

Member

|

|

|

Join Date: Nov 2014

Posts: 155

Likes: 1

Liked 163 Times in 58 Posts

|

|

Didn't know that cast steel and forged steel are the same. Now we can cast coil springs instead of taking all that time to draw wire and form them.

|

|

The Following User Likes This Post:

|

|

01-15-2015, 12:39 PM

|

|

SWCA Member

|

|

|

Join Date: Apr 2005

Location: Ohio

Posts: 111

Likes: 26

Liked 71 Times in 12 Posts

|

|

Quote:

Originally Posted by Alk8944

FWIW, ALL steel is cast! The cast billet is then processed by rolling, drawing, forging, piercing, turning, etc. Cast STEEL is not brittle as cast Iron or Aluminum usually are. Casting the steel directly in the form of a gun frame, slide or other part does not change this.

|

I spent 38 years in the specialty steel business and not all steel is cast. Two heats of the same metalurgical specs will have different properties if cast or poured as an ingot then rolled in a reversing mill with a manipulator. That being said, the properties of that steel can be changed by forging, annealing, normalizing, and heat treating. A forged metal would need to be annealed before machining then heat treated to specifications. I believe a S&W frame starts as a round and then forged, annealed,machined, then heat treated.

__________________

NRA Life

OGCA

|

|

The Following User Likes This Post:

|

|

01-15-2015, 09:07 PM

|

|

Member

|

|

|

Join Date: May 2001

Posts: 1,473

Likes: 0

Liked 1,052 Times in 453 Posts

|

|

Colt and S&W make their frames from forged steel.

The forge takes a lump of steel and heats it to a red heat ( precisely temperature controlled) then put it in a mold in a power hammer forge, which beats it into the mold.

What comes out looks like a rough pistol frame made from play dough.

The rough forging is then fully machined to final shape.

Ruger casts their frames and most other parts by the lost wax casting process that allows making almost fully finished parts needing only some final threading and machining and hardening.

Here's a raw forged Colt 1911 frame after removing the razor sharp "flash" from the forging.

|

01-16-2015, 08:39 AM

|

|

US Veteran

|

|

|

Join Date: Dec 2008

Location: New England

Posts: 4,173

Likes: 3,543

Liked 4,000 Times in 1,628 Posts

|

|

THOSE ARE 2 VERY INTERESTING AND INFORMATIVE POSTS, dwf6666 AND dfariswheel. THE COLLECTIVE BODY OF KNOWLEDGE ON THIS FORUM IS INCREDIBLE……….

__________________

'Nam 1968-69.DAV,VFW,NRA Inst.

|

01-17-2015, 02:28 AM

|

|

Member

|

|

|

Join Date: Oct 2014

Location: South Dakota

Posts: 379

Likes: 732

Liked 222 Times in 128 Posts

|

|

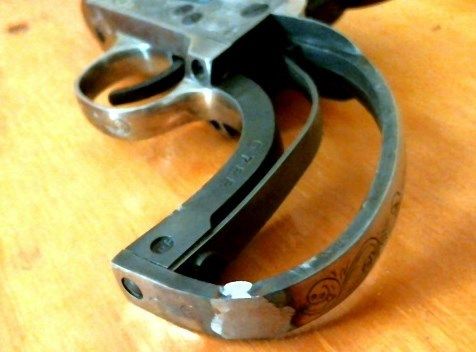

I recently read cover to cover a book on S&W two times. The "crane" was mentioned multiple times. Sorry fellas but I am still at a loss as to what part of the firearm this is. Will someone please send a picture of this area to the dumb , dumb in CO. Thank you!

|

01-17-2015, 03:31 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: (outside) Charleston, SC

Posts: 32,071

Likes: 43,349

Liked 30,653 Times in 14,420 Posts

|

|

Somebody who knows......

Somebody who knows......

Somebody who knows what they are doing can reshape a crane. I would only attempt it on a piece of junk and probably wouldn't have a good outcome.

__________________

"He was kinda funny lookin'"

|

01-17-2015, 03:34 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: (outside) Charleston, SC

Posts: 32,071

Likes: 43,349

Liked 30,653 Times in 14,420 Posts

|

|

Don't need a picture....

Don't need a picture....

Quote:

Originally Posted by S&W SS Revolvers

I recently read cover to cover a book on S&W two times. The "crane" was mentioned multiple times. Sorry fellas but I am still at a loss as to what part of the firearm this is. Will someone please send a picture of this area to the dumb , dumb in CO. Thank you!

|

There is a hinged arm that holds the cylinder in the front. When the cylinder is closed it fits into the frame, when the cylinder is out it's right there holding the cylinder. I think it's a part that's kind of taken for granted because you don't see it much when closed and open the cylinder is more impressive to behold.

__________________

"He was kinda funny lookin'"

|

01-17-2015, 09:43 PM

|

|

Member

|

|

|

Join Date: May 2001

Posts: 1,473

Likes: 0

Liked 1,052 Times in 453 Posts

|

|

Quote:

Originally Posted by S&W SS Revolvers

I recently read cover to cover a book on S&W two times. The "crane" was mentioned multiple times. Sorry fellas but I am still at a loss as to what part of the firearm this is. Will someone please send a picture of this area to the dumb , dumb in CO. Thank you!

|

Technically, while Colt and Ruger call it a "crane", S&W calls it a "yoke". Different names, used by different companies, but the same part.

Here's a S&W schematic.

The "yoke" is part number 31. It's the "arm" the cylinder rides on that swings out of the frame when the cylinder is opened.

http://www.brownells.com/schematics/...86-sid557.aspx

|

02-14-2015, 01:06 PM

|

|

Member

|

|

|

Join Date: Feb 2015

Location: clinton,new york

Posts: 11

Likes: 0

Liked 4 Times in 3 Posts

|

|

sprung crane

sprung crane

Quote:

Originally Posted by da gimp

Will even the S&W factory be able to repair one, or is a matter of too much cost to get it done? Years ago, I'd see some nice revolvers at gun shows with badly sprung cranes for bargain prices & had always passed them by.

my late father in law had purchased a used 586 that had a sprung crane when he got it, he rarely shot it & as far as I know made no effort to having it repaired.

thanks in advance for an answer, I reviewed all the old pages & FAQ's posted here & saw nothing discussing this.

|

contact me via email and I can advise you how to realign your cyl. . [email protected].

|

02-15-2015, 11:29 AM

|

|

US Veteran

|

|

|

Join Date: Oct 2013

Location: Central Montana

Posts: 14,840

Likes: 14,609

Liked 43,941 Times in 11,024 Posts

|

|

Quote:

Originally Posted by BigChief52

Didn't know that cast steel and forged steel are the same. Now we can cast coil springs instead of taking all that time to draw wire and form them.

|

A spring is made from cast steel. A cast steel billet is first rolled into bars ( a type of forging) then it is rolled into round stock. Larger dia. springs are made directly from round stock, smaller are drawn to dia. (again a type of forging) then formed. Annealing is done after forging then normalization, harden then temper. A S&W frame starts as a cast steel billet, then is rolled and then forged to shape. Even a piece of flat steel bar was "forged" when it was rolled from a billet. The grain thing about forging is a joke. A forging requires the piece to be annealed and normalized after forging or it would have extreme grain growth because of the elevated temps required for forging and be way brittle. Annealing, normalizing, hardening and tempering resets the grain structure and type of grain anyway.

On another note castings of steel have came a long ways. Steel is no longer cast in an open hearth. Quality steel castings are first smelted in an induction oven in an inert atmosphere. Then poured. This allows for very high quality castings without the inclusions or slag from older methods and produce very high quality.

The best alloys are produced in similar furnaces but, instead of cast into billets the molten metal is sprayed in an inert atmosphere producing small particles of steel that are EXTREMELY uniform in alloy content. These are then heated to near melting temps then pressed into a solid billet. Near perfect steel billets with no stratification. You are more apt to make this type of steel worse by forging it and not better.

I make custom knives I both grind from flat bar and forge from bars or round stock. Forging has its own perils and requires careful controls not to destroy the steel in the process and to get its "grain" back into shape after the forging process causes it to have excessive grain growth. To forge you must raise the steels temp way above its critical temp to reshape. Temps above critical cause grain growth which is a bad thing, which must be reset by normalization before hardening and tempering.

Yes, I am a steel freak. I study it and learn about what REALLY happens in the processes. I know and converse occasionally with metallurgists and know and talk with some engineers on a regularly when I am working.

When did new processes become "BAD". We used to herald them. Just like MIM. 95% of the people who knock it don't actually have a real clue how it works or how good it is. I hear comment like it has plastic in it. LOL. Anything but the steel is long gone in the finished product. Ask an aerospace engineer what he thinks of MIM vs forged.

I cracks me up that guys who love S&Ws (I am one) which are forged recommend that if you want to shoot heavy loads to do it in a cast Ruger! Thompson uses castings and they are shooting high pressure rifle rounds regularly.

Last edited by steelslaver; 02-15-2015 at 11:41 AM.

|

|

The Following 2 Users Like Post:

|

|

02-15-2015, 12:37 PM

|

|

Absent Comrade

|

|

|

Join Date: Aug 2006

Location: Ardmore, OK

Posts: 790

Likes: 781

Liked 2,437 Times in 364 Posts

|

|

I've had a lot of experience with carbon steel, from SAW 1095 to old saw blades & files, making springs & other gun parts. Got involved lately with cast steel & am impressed with it in a Pietta latest model SAA copy. In some respects copied & others their idea of improved. Cast Italian steel, obviously cast seeing mold marks, machined on fit & finish surfaces, seems very much like what I have encountered in early 1900s Colts. It bends, welds, cuts & engraves pretty much the same.

Latest project --

|

|

The Following User Likes This Post:

|

|

02-17-2015, 06:32 PM

|

|

Member

|

|

|

Join Date: Nov 2014

Posts: 155

Likes: 1

Liked 163 Times in 58 Posts

|

|

No, springs can't be cast. Billets are cast but springs must be drawn or forged.

|

|

Posting Rules

Posting Rules

|

|

|

|

|