I know this is an old thread, but the lack of a commercially produced facing tool is a continuing problem that I finally solved for myself today.

I could have made a mandrel and used a brownells barrel facing cutter mentioned above but I wanted a non-handheld solution as I do not like the results I get from the brownells cutter when facing barrels installed in a frame.

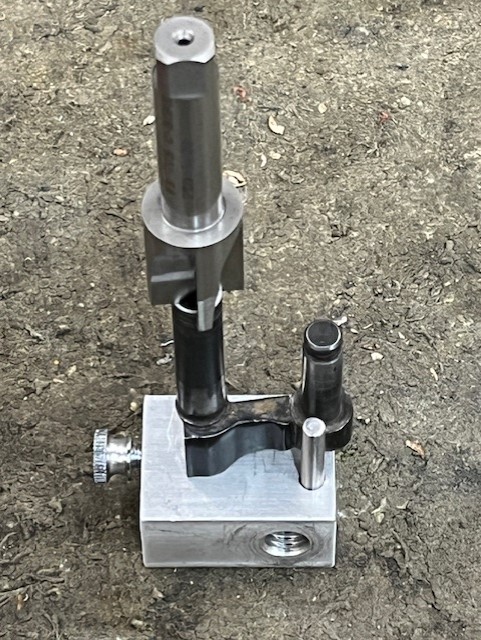

I ground a mandrel that slips into the yoke and allows me to mount the mandrel and yoke in a piece of aluminum in my milling machine vise that allows me to hold the crane pointing up.

I ground a 0.310" floating reamer pilot (as used for rifle barrel chambering reamers) and used it on one of these 0.705" breech counterbore that I already have:

This allows me to setup a yoke in the mill and use my micrometer quill stop to set the length.

This gives me better results that a handheld facing cutter.

When I am done with the job, I use the mandrel to hold the bushing on the block.

The thumbscrew on the left holds the mandrel in the block.

The dowel pin on the right keeps the yoke from rotating while you are facing it.

I saw it mentioned somewhere that someone made a yoke mandrel to put into a wilson case trimmer.

That should also work great as well since you can precisely set the stop length.