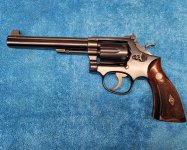

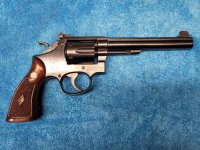

I just purchased this K38 Target Masterpiece a few days ago. The first thing I noticed, besides it being beautiful, was in single action you just BARELY touched the trigger and the hammer would drop, which I didn't like at all! Once inside I found the hammer notch did not have a sharp edge and the sear was rounded. It looked like someone possibly got in there at some point and stoned some of the front edge off, I'm not sure. I proceeded to get the proper angles on the sear using an extra fine Arkansas stone, but I do believe I'm through the case hardening as it was pretty easy stoning. The trigger definitely feels great now, and safe, and the pull is now at 3 lbs and really smooth. The hammer has no push off now as it did before. I pushed it forward from all angles and it is locked solid. My question is... does this sear need to be hardened in some way or will it be ok the way it is. I'm not sure how hard, or soft, the metal is if I'm indeed through the hardening. I won't be shooting it that often, I would say maybe 500 rounds a year if that. I'm hoping it will be fine for a few years or more. I'm sure it's not easy finding a target trigger! Any thoughts and opinions appreciated.

Attachments

Last edited: