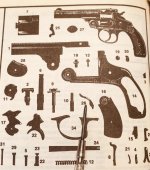

I have a 32 double action top break nickel that looks really nice, but when I thumb cock the pistol and put just a little pressure on the back of the hammer it breaks. I think this is a 3rd model double action.

My question and I understand I should post pictures, but is this just a sear problem or is this a design problem with this model?

My question and I understand I should post pictures, but is this just a sear problem or is this a design problem with this model?