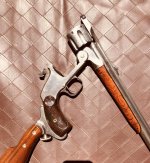

I have wanted to test out my .320 Revolving rifle but did not want to mold bullets from a very expensive original Revolving Rifle Mold. Photo 1

Been waiting for a 32 IDEAL MOLD to show up. One finally did. Photo’s 2&3,4.

So I plan on using the same case that I used for shooting a target 32-44. The 32/20 WCF using a mouth expander to size up to .323.

Photo 5.

The case won’t be able to handle the original 17 grains of black powder but I’m pretty sure I can get 15 grains into the case with the longer bullet. I expect to see some excellent accuracy from the longer 115 grain Ideal rifle bullet. The design specs match the Revolving Rifle perfectly.

We shall see. I still have to mold bullets and run one down the barrel to prove the bore specs so not quite there yet. I also need to do a little more research on the cartridge specs. I want to get as close as possible to original design.

Murph

Been waiting for a 32 IDEAL MOLD to show up. One finally did. Photo’s 2&3,4.

So I plan on using the same case that I used for shooting a target 32-44. The 32/20 WCF using a mouth expander to size up to .323.

Photo 5.

The case won’t be able to handle the original 17 grains of black powder but I’m pretty sure I can get 15 grains into the case with the longer bullet. I expect to see some excellent accuracy from the longer 115 grain Ideal rifle bullet. The design specs match the Revolving Rifle perfectly.

We shall see. I still have to mold bullets and run one down the barrel to prove the bore specs so not quite there yet. I also need to do a little more research on the cartridge specs. I want to get as close as possible to original design.

Murph

Attachments

Last edited: