- Joined

- May 28, 2025

- Messages

- 28

- Reaction score

- 14

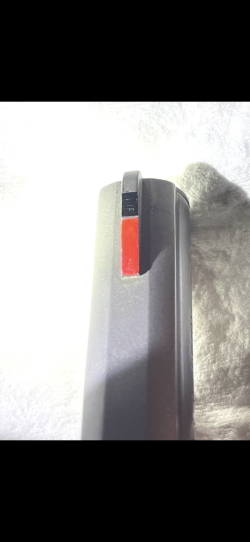

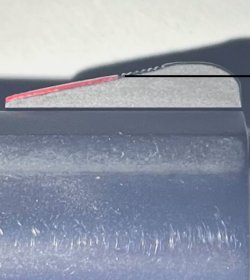

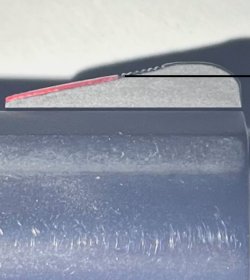

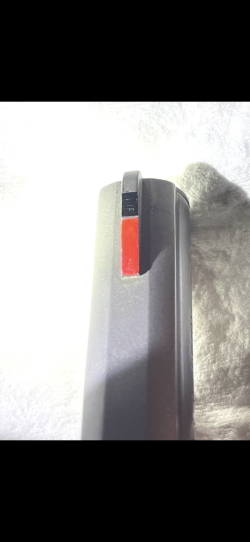

It's .095" too tall, all ammo 125gr Special to 180gr Buffalo Bore Magnum have a mean center of 7" low at 15yds. I'm doing well with a paint scheme, essentially putting the black rectangle on anticipated point of impact, but it's a lot to concentrate on. I don't know how to take it down to the appropriate height, and make it look decent, without increasing the slope on the ramp. Be nice to remove it, take the .095" from the bottom and reattach lol.

Any suggestions?

Any suggestions?