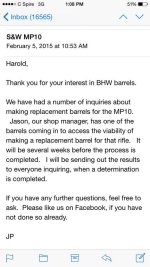

Yesterday, I spoke with Jay at BHW

Black Hole Weaponry and find that they just received a second customer's barrel, which was split wide open. I believe it belongs to a previous poster here- wish he would chime in and keep us updated!

Bottom line is that S&W extensions have the index pin only installed into the extension and not through into the barrel. Meaning; The extension can be torqued off the S&W barrel, allowing for the replacement barrel to be fitted to it. Apparently, so far at least, the factory thread-job on the original components has been clean.

So relax, if your factory barrel blows out

You just get a shot of adrenaline and CAN have it replaced with another barrel of your choice.

There is a possibility that BHW may be able to have BAT Machine supply them with S&W pattern extensions that they could market (depending on S&W patents- if any??). Be nice to be able to have a custom barrel to install with the ability to put the factory pipe back onto your MP-10 when it becomes time to sell it- EH?