rednichols

Member

- Joined

- Jul 24, 2012

- Messages

- 2,745

- Reaction score

- 8,484

From time to time I, and others, comment on today's Bianchi quality vs. 'the good old days'. There is a third, pre-Red (1970)quality period, too  .

.

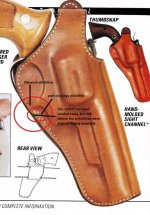

Consider this image as a 'thread starter'. It's the back cover of Bianchi's 1968 catalogue:

All looks pretty normal, I expect. 1970, I'm 20, and I'm interviewing with John to come to work at the company. He's been operating just 4 years, both Bruce Nelson and Gordon Davis have come and gone in that time. And during a break from that -- spent the day there -- I wander amongst the stock rows and glory in the 'autumn leaves' I find there: all the browns are in every shade of tan from white to red to nearly black.

Turns out, though, when I become part of the team, they're not supposed to be different colours! One can't match the various bits -- holster, belt, pouch -- into sets; orders for sets have to be made up together.

That's because, at that time, the company had no control over its processes. The pale whitish ones had been dried inside because, for example, it was raining. The reddish ones dried outside in the hot sun; this literally gives a sunburn. The really dark ones, nearly black, had been dropped into the neatsfoot oil. The 'perfect' ones; well, who knew how that was done.

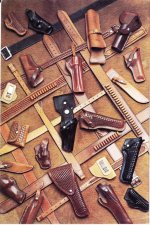

So one of my jobs, over time (1970-1987) was to 'produce' the company catalogues. Not such a biggie whilst the catalogues were in b&w, but John had decided to produce the industry's first all-colour catalogues. Now the mismatches were a problem: we had to actually hand make every holster, belt, pouch, keeper for the pics. And not just for colour; for moulding, for finish, for stitching, for every kind of quality benchmark.

Over time, once I'd been given responsibility for quality assurance at the company, quality rose from there to being able to reach into any/all inventory box without looking (many were above head height) and take it to the photographer. Every product was perfect or it hadn't cleared quality assurance; and we didn't throw much away, because any/all flaws were caught long before they got to the final stage.

Today the company has lost track of what they once knew about quality, and we can't blame it on Mexico production, because I've worked in maquiladoras and the locals are proud to make the best -- when they are told what it is, and rewarded for making it happen. Here I'm not necessarily speaking about colour; I'm using that simply as a basepoint for further education about leather holster quality.

Consider this image as a 'thread starter'. It's the back cover of Bianchi's 1968 catalogue:

All looks pretty normal, I expect. 1970, I'm 20, and I'm interviewing with John to come to work at the company. He's been operating just 4 years, both Bruce Nelson and Gordon Davis have come and gone in that time. And during a break from that -- spent the day there -- I wander amongst the stock rows and glory in the 'autumn leaves' I find there: all the browns are in every shade of tan from white to red to nearly black.

Turns out, though, when I become part of the team, they're not supposed to be different colours! One can't match the various bits -- holster, belt, pouch -- into sets; orders for sets have to be made up together.

That's because, at that time, the company had no control over its processes. The pale whitish ones had been dried inside because, for example, it was raining. The reddish ones dried outside in the hot sun; this literally gives a sunburn. The really dark ones, nearly black, had been dropped into the neatsfoot oil. The 'perfect' ones; well, who knew how that was done.

So one of my jobs, over time (1970-1987) was to 'produce' the company catalogues. Not such a biggie whilst the catalogues were in b&w, but John had decided to produce the industry's first all-colour catalogues. Now the mismatches were a problem: we had to actually hand make every holster, belt, pouch, keeper for the pics. And not just for colour; for moulding, for finish, for stitching, for every kind of quality benchmark.

Over time, once I'd been given responsibility for quality assurance at the company, quality rose from there to being able to reach into any/all inventory box without looking (many were above head height) and take it to the photographer. Every product was perfect or it hadn't cleared quality assurance; and we didn't throw much away, because any/all flaws were caught long before they got to the final stage.

Today the company has lost track of what they once knew about quality, and we can't blame it on Mexico production, because I've worked in maquiladoras and the locals are proud to make the best -- when they are told what it is, and rewarded for making it happen. Here I'm not necessarily speaking about colour; I'm using that simply as a basepoint for further education about leather holster quality.