You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Case Trim Length

- Thread starter wylie won

- Start date

Register to hide this ad

The Norseman

Member

223 case length

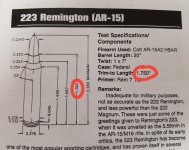

I just obey the picture.

All my reloaded Rifle or Pistol Cartridges

are trimmed one thousands under.

I just obey the picture.

All my reloaded Rifle or Pistol Cartridges

are trimmed one thousands under.

rockquarry

Member

- Joined

- Aug 9, 2005

- Messages

- 8,493

- Reaction score

- 10,417

1.76" is maximum permissible length for .223. Don't use brass longer than that. The 1.75" length is a suggested trim length.

It says "trim-to length 1.75". It doesn't get much clearer than that.

hdwhit

Member

wylie won wrote:

What is the plus or minus for 223 as it relates to the case?

If we're talking about dimensioning, then it would be 1.760 - 0.010

The 1.760 refers to the "max" length, as noted. The 1.750 is the "trim to" length as noted in the pic. The SAAMI dimensions I've seen are case length 1.760" -.030" and one pic says 1.760" - .032". The -.020" was from a google search image, the -.030" was from the SAAMI site. I'd go with .1730"-1.760"...

DWalt

Member

What is more important is the case length consistency. At least if you are concerned about grouping performance.

Twoboxer

Member

1.760 is the max length guaranteed to fit your rifle's chamber. 1.761 (or larger) may or may not fit.

When trimming brass (after sizing), it is relatively normal to trim 0.010" shorter than max length . . . in this case the trim-to length specified (recommended) is often 1.750. This will usually allow more than one firing and re-sizing before trimming is again necessary.

In 223/556, 1.740" is sometimes recommended because (a) it doesn't matter, and (b) gives more firings before trimming is again necessary. You will find several factory ammo brands (eg Federal) where the case length is 1.740" or shorter.

When trimming brass (after sizing), it is relatively normal to trim 0.010" shorter than max length . . . in this case the trim-to length specified (recommended) is often 1.750. This will usually allow more than one firing and re-sizing before trimming is again necessary.

In 223/556, 1.740" is sometimes recommended because (a) it doesn't matter, and (b) gives more firings before trimming is again necessary. You will find several factory ammo brands (eg Federal) where the case length is 1.740" or shorter.

Ivan the Butcher

Member

Try trimming 15 brass to 1.74 and see how they measurer after shooting them. For reference sake, mark and keep one unused, reload and repeat. You will then know how your rifle and loading die combo treat your brass.

The sizing of the neck and pulling a button through it, to bring it back up to size, shortens the life of the brass and cause to stretch excessively. The other type of sizing uses changeable collets (size based on neck wall thickness) to take the neck diameter to a very specific diameter (+/-.001" diameter, and .0005 for one brand). You can get these dies in Full Length Size or Neck Size. With this method I have one bolt action 223 that I trim the brass every 10 loadings, weather they need it or not! My AR I trim every 3 loadings (I could go 4 or 5, but try to keep everything the same!)

Like a previous poster said, Consistency is the important part!

When trimming, some trimmers have a little difficulty getting the shell base consistently tight into the shell holder, This can end up making a hole batch very by up to 3/100" in length (I had this happen several times with an old RCBS system). Lee's & L.E.Wilson's are the best for consistency in length. They are respectively, the least and most expensive!

Ivan

The sizing of the neck and pulling a button through it, to bring it back up to size, shortens the life of the brass and cause to stretch excessively. The other type of sizing uses changeable collets (size based on neck wall thickness) to take the neck diameter to a very specific diameter (+/-.001" diameter, and .0005 for one brand). You can get these dies in Full Length Size or Neck Size. With this method I have one bolt action 223 that I trim the brass every 10 loadings, weather they need it or not! My AR I trim every 3 loadings (I could go 4 or 5, but try to keep everything the same!)

Like a previous poster said, Consistency is the important part!

When trimming, some trimmers have a little difficulty getting the shell base consistently tight into the shell holder, This can end up making a hole batch very by up to 3/100" in length (I had this happen several times with an old RCBS system). Lee's & L.E.Wilson's are the best for consistency in length. They are respectively, the least and most expensive!

Ivan

I used to have the difficulty keeping consistency with the older collet type RCBS trimmer. The newer trimmer with shell base holders is much more consistent. I always trim minimum recommended length. It seems if you can neck size only (primarily bolt guns) you don't need to trim as often as full length sizing.

FWIW, I size all my .223 to 1.750" because that's what my trimmer is set at. I usually tell new reloaders of popular cartridges with easy to find brass to not worry much about case life now, just get good, shootable ammo now and think about case life later...

Last edited:

Twoboxer

Member

Hopefully this won't sidetrack the thread, but I personally found the following very interesting, if a little confusing at first:

Starting a new batch of Lapua brass (in this case 308), I decided to take a bunch of measurements on 10 at random and mark them so they could be tracked. They were measured as delivered and then again after neck sizing before first firing.

After firing, the cases' base-to-ogive measurements were all longer, and the overall lengths were all shorter. The necks had been pulled down as the rest of the case was pressure-adapted to the size (diameter) and profile (shoulder angle) of the chamber.

After sizing, the overall length grew as expected when the cases were squeezed in and and the shoulders bumped back.

Starting a new batch of Lapua brass (in this case 308), I decided to take a bunch of measurements on 10 at random and mark them so they could be tracked. They were measured as delivered and then again after neck sizing before first firing.

After firing, the cases' base-to-ogive measurements were all longer, and the overall lengths were all shorter. The necks had been pulled down as the rest of the case was pressure-adapted to the size (diameter) and profile (shoulder angle) of the chamber.

After sizing, the overall length grew as expected when the cases were squeezed in and and the shoulders bumped back.

Similar threads

- Replies

- 7

- Views

- 568