Lots of drama since I first posted this thread. My Taylors/Uberti cam became sacrificial, as I drilled it to accept the original bushing & filed a new notch at the 6:00 position with the 'ear" pointed up. Reading that the extractor rods are not interchangeable between first & 2nd models & having 2 identical, the Tayors/Uberti became sacrificial. Having it and a sandpaper flap wheel on my bench grinder, I made uncountable trips from the wheel to the gun. Suddenly HOO-RAH, I received complete extraction & return or "snap back". Then another issue raised its ugly head. The "base pin", which is really a metal tube with a hidden slot in the bottom, threaded to enter under the barrel had moved off center, blocking the cam. Finding a barely visible "index?" mark in the exposed end, I found it to be in alignment with that slot. Returned it to center. Back in business. This could be a future candidate for blue Loc-Tite. I had received from Popperts, a replacement Schofield extractor as the star was broken off the grooved shaft of the original but still held in place by the stud. Upon removal of it, I could see some wobble, thus the replacement from Popperts. Even with the broken extractor, I had perfect chamber indexing. Now, I do not. Evidently, the relationship has changed between the sprocket & the hand. Now, I must bump the cylinder by hand, perhaps 1/16th of an inch to achieved proper indexing. Removed the grips & side plate. Put her in a vise. Found plenty of spring tension on the hand. Applied pressure to the back of the hand as I pulled the hammer to full cock. No help. Tip of hand appears perfect...but..what do I know? What I now have is full extraction & less than perfect indexing. I'm reminded of what Chicione says in his book, finding that "wear" transmits itself from one place to the next. Did not someone in the Army say "too many parts"? Having 2 U.S. issued Colt SAAs from the same year showing similar amounts of wear & abuse but still with perfect function (timing & lock-up), my personal testimony is yep...too many parts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First model Schofield extraction issue (revisited)

- Thread starter Old Dave

- Start date

Register to hide this ad

Ivan the Butcher

Member

Two steps forward, one step back and one step sideways!

Ivan

Ivan

OH YES! I had failed to mention how upon further examination, it was very visible that where the stud met the recoil shield, it had peened the bottom of the slot from MANY, MANY repeated vigorous closures of the action! I still enjoy having this old girl as with serial of 739 (uncut), in a first model she would obviously have a lot to say. Even the grips have a story, being serially numbered to a 2nd model & likely an armorer's replacment. She is in retirement, firing only my black powder blanks.

mmaher94087

Member

Dave, does this 1/16th inch non-lock happen on all charge holes or only one or two? Compare the teeth of the extractors to each other. I suspect the new extractor teeth are a shade smaller in diameter than the old one. A micrometer helps.

A quick operation primer: The hand catches the bottom of the tooth of the extractor (9 o'clock) and pushes up starting the rotation. The hand then slides to the left of the tooth rotating the cylinder to the right as the cylinder locks.

If the "follow-up" is short, as in your case, the offending tooth or teeth can be peened to widen it/them slightly. I place the extractor flat on my vise jaws and peen the tooth/teeth with a flat-faced punch and hammer. Patience and trial fitting - wash, rinse, repeat.

A quick operation primer: The hand catches the bottom of the tooth of the extractor (9 o'clock) and pushes up starting the rotation. The hand then slides to the left of the tooth rotating the cylinder to the right as the cylinder locks.

If the "follow-up" is short, as in your case, the offending tooth or teeth can be peened to widen it/them slightly. I place the extractor flat on my vise jaws and peen the tooth/teeth with a flat-faced punch and hammer. Patience and trial fitting - wash, rinse, repeat.

Thanks! Every chamber needs help. I note that the hand is at the outer edge of the "window" for it when the hammer is all the way down & it immediately extends the instant that I move the hammer, failing to engage any rachet tooth unless I help it at really any point between chambers. Only then does it follow through to the end (full cock). Tomorrow, I will put my micrometer on each tooth of the broken star & compare with the replacement. Yes, I have several flat punches. Thanks again for the suggestion.

- Joined

- Dec 1, 2022

- Messages

- 877

- Reaction score

- 1,418

Hi There,

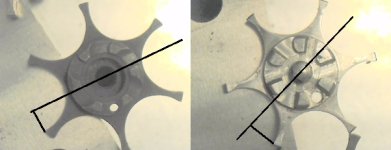

I have both an original Schofield extractor and a repro one. I

took some pics and created a comparison between the two.

What I notice is the ratchet pads have a different timing re-

lationship between the two. As I see it, the repro part has

a slightly later timing (which you have verified).

Peening those pads could restore correct timing but it will be

peen and test each pad until all six are restored. I don't know

what equipment you have or have access to, but making a

new hand may be simpler. Alternatively, you could weld-up

the top of the original hand to make it a little longer.

Personally, I would make a new hand. That way, you can re-

turn the gun back to its original state. But that is me.

Cheers!

Webb

I have both an original Schofield extractor and a repro one. I

took some pics and created a comparison between the two.

What I notice is the ratchet pads have a different timing re-

lationship between the two. As I see it, the repro part has

a slightly later timing (which you have verified).

Peening those pads could restore correct timing but it will be

peen and test each pad until all six are restored. I don't know

what equipment you have or have access to, but making a

new hand may be simpler. Alternatively, you could weld-up

the top of the original hand to make it a little longer.

Personally, I would make a new hand. That way, you can re-

turn the gun back to its original state. But that is me.

Cheers!

Webb

Attachments

Last edited:

I was very intimidated this morning with the prospect of needing to undo something that might be impossible for me to undo. PEENING! While studying the 2 sprockets, I opened the action to once again find that the slot in the base pin had shifted off center, preventing the cam from contacting the extractor rod. Being fed up with that scenario, I removed the cylinder & base pin, degreased the threads on the pin and under the barrel. Next step was blue loc-tite applied with a toothpick. Having previously measured how far that I left the pin protrude from the barrel assembly, I left it stick out a bit further, assuring myself that the slot was centered. Let it cure today. The extraction process was restored as I expected. Next was a very pleasant surprise. PERFECT chamber indexing. Evidently, I provided the cylinder with just enough push to the rear for the sprocket teeth to meet the hand with no help as before! HOO-RAH! Another thought. I had originally installed the base pin under the barrel at a measurement reflected in my Chicoine book. I'm suspecting that measurement was based on factory new specs. By my installation of having it longer, perhaps made up for a wear factor. Reflecting again on what Chicione said about 'wear" transmitting itself from one place to another. Lots of trial & error involved. Original specs? Forget them. I'm not creating a new gun from something that's seen what this one has. I consider myself fortunate to have her in operational condition especially from such a violent period in our history.

Last edited:

mmaher94087

Member

Dave, you are extremely lucky. Those old base pins often break off from rusting in place or they collapse from the torque and clamping pressures required to remove them. Buy a lottery ticket.

Similar threads

- Replies

- 7

- Views

- 614

- Replies

- 1

- Views

- 780