emjayw

Member

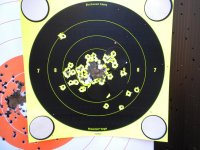

Thought I'd post this as I just returned from another range session with my 15-22. As I've stated in previous posts, my barrel nut keeps backing itself out as I shoot. After the last session two weeks ago, I came home and removed the barrel and thoroughly degreased the thread area and the barrel nut, then put just a touch of lubricant back on the threads and torqued it with the "tool" as tight as I could twist it without a barrel vise. Today I continued my 30 yard efforts with a new, cheap ($32) Tasco Red Dot from Wal-Mart. It took me a while to "see" the correct sight picture as my 62-year-old eyes don't focus as well as they once did. Once I settled in, so did my groups. I was really knocking the crap out of the bull at 30 yards with that 5MOA dot covering it! My last 25 round magazine was a disappointment however. I wasn't sure what to think until I got home and checked the barrel nut again...it had backed off a full 3/4 turn during those last 50 rounds! I re-torqued it again but I'm getting ready to add a drop of Blue Loctite to the threads this time. I love this little rifle. It never fails to feed, shoot or eject..if only I could keep the barrel tight! Here's a shot showing my final target with the first 25 rounds cutting a nice hole in the bull and the last 25 getting further and further left and low. hope this is an isolated problem. I may contact S&W about it but I don't want to be without my 15-22 for very long. Note: mine was purchased in October '09 at a gun show in Fort Worth, TX and has been stone reliable for over 2500 rounds. Mike in TX