Very common on old revolvers with lots of rounds thru them over the years, and even newer revolvers with high use.

CARRY UP SUMMARY:

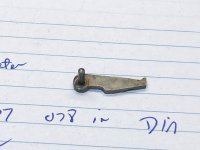

When the cylinder is a few thousandths short of advancing completely to lock up, known as "carry up", peening the teeth to 'upset' metal on the extractor star is much simpler than finding and fitting a new hand.

The hand is made of harder steel than the teeth since it has six times the contacts of each tooth, and this is a typical result after many rounds of shooting. That's why I would not install a new hand, it already has the advantage.

With the cylinder open in a vertical position, use a flat tipped punch to very gently peen each of the offending teeth of the 6 ratchet teeth on the rear vertical surface of the edge contacted by the hand. One tap on each tooth will usually do it and the gun will function perfectly for another 20+ years. I've fixed so many that way I can't count them.

Caution note: Before peening, first assess for excessive cyl end play and/or yoke end play. These should be addressed before any peening is attempted. Also be sure that neither the trigger or hammer stud is not loose or broken, or that the extractor rod or particularly the yoke are true and not bent. If more than gentle tapping seems required to upset the star teeth, to the point of being obvious, there may be severe wear or other issues involved.

DETAILED CARRY UP REPAIR:

You have a "carry up" problem. You can fix it faster than you can read the explanation and 'how-to' below w/o any new parts.

The issue is a failure to "Carry Up". In other words the hand does not carry the cyl far enough to lock up within the normal cycle distance of the hammer travel. Usually it doesn't show up in DA shooting because of the momentum of the faster cyl rotation.

Based on your assessment and comments, I believe Pat Sweeney's "Gunsmithing Pistols & Revolvers", 2nd Ed.(2004), pp.219-220 is the most sensible, perfectly good solution, what I would do and have done many times, what S&W factory trained smiths have done in similar situations, and also what members on this forum have done successfully after reading about it, which is:

Peening the ratchet tooth (or teeth) to correct timing/cyl 'carry up' is simple.

Replacing and fitting a new hand may fix your problem and may not, but the hand is not likely needed or at fault. It's the harder part compared to the cyl teeth.

The flat surfaces of the teeth facing you when looking at the rear face of the cyl are where to peen. The tooth at about 3 o'clock is the next to be engaged by the hand (when cyl is closed) to advance the chamber to the right of the one at 12 o'clock, into firing position. The cylinder turns counterclockwise so the hand will engage the 'bottom side' of that tooth. The flat surface facing you is where to peen, on the edge right above the bottom side of the tooth. No need to take the gun apart at all. I lay the gun on a padded surface on its right side, muzzle pointing to the left (I'm right handed) with cyl propped open with a rolled up shop cloth.

If you're worried about force to the yoke and frame, I'm afraid that you're envisioning TAPPING TOO HARD. Just a very light peen with a small hammer and flat tip punch is all that's needed to 'upset' the metal. The ratchet teeth are not hardened! This takes finesse, not force.

And by laying the gun on a padded surface without restraint as I described, it's allowed to move when the punch is tapped with the hammer, mitigating any force to the yoke and frame.

You may not even see the metal 'upset' from tapping the punch and it can be enough to solve the problem. One light tap with a small light hammer and flat face punch then close the cylinder and try it. If the cylinder doesn't 'carry up' or even if it does C/U but still has too much 'looseness' when fully cocked, give the tooth another tap. You can do all six teeth, or just others where there's looseness with the chamber in firing position when the hammer is cocked.

Rough handling/constant double action rapid fire can accelerate the teeth deformation but it did not happen overnight, and now you have another 20+ years of shooting before it'll need anything more, depending of course on how much you shoot the gun. I've never had to do the same gun twice.

If you peen too much and the cylinder carries up too far that puts cocking the hammer in a bind or the bolt 'jumps' out of the cyl notch, not a problem, peen the surface that the hand contacts and push it back.

I would not put up with a carry up issue especially when it's so simple to fix. Everyone that has tried this has been successful.

Hope this helps you,