Rod Henrickson

Member

- Joined

- May 1, 2025

- Messages

- 6

- Reaction score

- 5

So, here in lays the conundrum. I managed to lay my hands on a S&W #3 Target in 32-44 S&W in what I can best describe as 100% mechanical condition. I suspect the owner bought it back in 1897 and shot it a few times and it then went into the sock drawer because the ammunition was hard to get and the thing was just a bit to anemic for shooting anything tougher than paper. Of course in Communist Canada this sort of critter is classed as an antique and I can actually take it out and shoot gophers to my hearts content with the it. Now I know some of the collectors on this board might be freaking out at the very notion of such nonsense and my heart bleeds for you, I'm still going to shoot it. I have been a full time gunsmith for over 40 years since getting out of CST in Denver so I'm semi retiring and I figure it's my turn to start wreaking stuff.

I've laid my hands on 500pc of new 32-20 brass and have dies coming from CH for the 32-44 S&W. This is where things are going to get a bit hinky, possibly even kinky. I'm going to use the Speer 32 caliber .314", 98 grain, lubed lead HBWC bullets. What I'm going to do is make a set of bump-dies and invert the bullets and reform the hollow base of the wadcutter into an ogive that resembles a 22LR bullet. At the same time I will bump the diameter up to .321" which is what that old model #3 was designed to use.

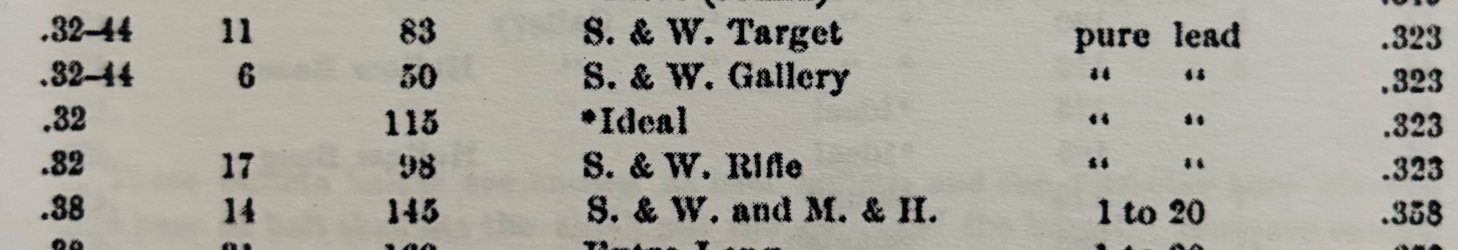

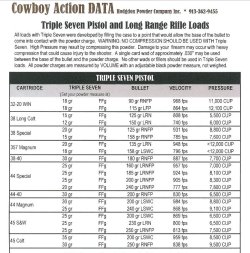

I may be crazy but I'm not nutz and I don't want to ruin the gun so I'm going to stay totally away from smokeless powder because the gun was never designed for it. There is no real loading data out there for this cartridge outside of the 2 loads listed on the factory fodder from the paleolithic era and nothing at all for a 98 grain bullet. So my powder of choice will either be FFFg black powder or Pyrodex P. Logic tells me that 10 grains of either should give me about 700 FPS and I won't run any risk of (SQUIBBING) the bore or causing any pressure related damage to the gun. Does that load seem to heavy? To light?

Also, black powder should be loaded with zero air space to prevent flash overs, but is there any risk of the bullets working forward in the cases under recoil? I understand that the original factory loads were deep seated in the case with no crimp but for some reason that whole idea seems a bit spooky to me!

If anyone can see any ideas or issues with my twisted thinking. Please feel free to chip in. I'm Canadian, so handguns are not my forte.

ADD NOT: Does anyone know for sure how these old #3 Targets were blued? Were they that horribly tough Carbona blue that you have to peal off with a blow torch and air chisel, or were they caustic blued? Not that I would ever entertain the thought of tossing a fine, collectable into the bluing tanks . . . . . . . . . . . . . . .

I've laid my hands on 500pc of new 32-20 brass and have dies coming from CH for the 32-44 S&W. This is where things are going to get a bit hinky, possibly even kinky. I'm going to use the Speer 32 caliber .314", 98 grain, lubed lead HBWC bullets. What I'm going to do is make a set of bump-dies and invert the bullets and reform the hollow base of the wadcutter into an ogive that resembles a 22LR bullet. At the same time I will bump the diameter up to .321" which is what that old model #3 was designed to use.

I may be crazy but I'm not nutz and I don't want to ruin the gun so I'm going to stay totally away from smokeless powder because the gun was never designed for it. There is no real loading data out there for this cartridge outside of the 2 loads listed on the factory fodder from the paleolithic era and nothing at all for a 98 grain bullet. So my powder of choice will either be FFFg black powder or Pyrodex P. Logic tells me that 10 grains of either should give me about 700 FPS and I won't run any risk of (SQUIBBING) the bore or causing any pressure related damage to the gun. Does that load seem to heavy? To light?

Also, black powder should be loaded with zero air space to prevent flash overs, but is there any risk of the bullets working forward in the cases under recoil? I understand that the original factory loads were deep seated in the case with no crimp but for some reason that whole idea seems a bit spooky to me!

If anyone can see any ideas or issues with my twisted thinking. Please feel free to chip in. I'm Canadian, so handguns are not my forte.

ADD NOT: Does anyone know for sure how these old #3 Targets were blued? Were they that horribly tough Carbona blue that you have to peal off with a blow torch and air chisel, or were they caustic blued? Not that I would ever entertain the thought of tossing a fine, collectable into the bluing tanks . . . . . . . . . . . . . . .

Attachments

Last edited: