infrared35

Member

- Joined

- Sep 12, 2010

- Messages

- 25

- Reaction score

- 16

Howdy; been a while since I've been on here so I apologize if this has been covered before, but I dug around a bit and didn't see anything specifically addressing it.

I just bought a moderately used 65-3 because I couldn't say no to the price; I suspect it was priced attractively because the seller was having issues with it. I'm not afraid of troubleshooting or even taking these things apart, so I wasn't worried about wrenching on it if I needed to, but this is a new issue for me.

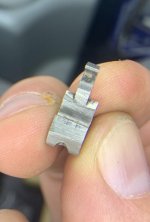

The trigger pull has a definite hitch in it, and it's particularly bad on one chamber. Running the gun through some tests, it seems that the cylinder stop isn't retracting enough to get out of the way completely as the cylinder wants to start turning. The stop still sticks up through the frame a little through the entire trigger press, where on my other K Frames it goes down flush with the frame and does so very quickly so the cylinder can start turning.

I'm guessing I need a new cylinder stop which isn't a big deal, but I wanted to run it by the group in case there was something I haven't considered. I've had the sideplate off and the trigger out and the stop seems to move freely; it just doesn't go down as far as it should or as quickly as it should. It didn't look like the trigger nose had been modified or anything like that.

As to why it seems worse on one particular chamber, that has yet to be seen. I'm thinking maybe a burr in the corresponding stop notch? Maybe a burr on a lug of the ejector star that makes it want to rotate a little sooner than the other chambers? The ejector rod is nice and straight and the cylinder moves freely otherwise, and yes, I've cleaned the heck out of the cylinder and ejector star and where they meet.

I just bought a moderately used 65-3 because I couldn't say no to the price; I suspect it was priced attractively because the seller was having issues with it. I'm not afraid of troubleshooting or even taking these things apart, so I wasn't worried about wrenching on it if I needed to, but this is a new issue for me.

The trigger pull has a definite hitch in it, and it's particularly bad on one chamber. Running the gun through some tests, it seems that the cylinder stop isn't retracting enough to get out of the way completely as the cylinder wants to start turning. The stop still sticks up through the frame a little through the entire trigger press, where on my other K Frames it goes down flush with the frame and does so very quickly so the cylinder can start turning.

I'm guessing I need a new cylinder stop which isn't a big deal, but I wanted to run it by the group in case there was something I haven't considered. I've had the sideplate off and the trigger out and the stop seems to move freely; it just doesn't go down as far as it should or as quickly as it should. It didn't look like the trigger nose had been modified or anything like that.

As to why it seems worse on one particular chamber, that has yet to be seen. I'm thinking maybe a burr in the corresponding stop notch? Maybe a burr on a lug of the ejector star that makes it want to rotate a little sooner than the other chambers? The ejector rod is nice and straight and the cylinder moves freely otherwise, and yes, I've cleaned the heck out of the cylinder and ejector star and where they meet.