Teufelhunden82

Member

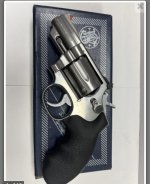

I just picked up a 66-2 snub with matching numbered box, docs and tools off the auction site for $1032. It locks up tight, has no end-shake. Two things I noticed immediately was the rear site is a little wobbly (wiggles slightly fore and aft). I would actually prefer a white-outlined rear site if it has to be replaced, so I'm not too worried there. I also noticed the cylinder would bind slightly just before it reached the fully open position. I figured this was due to dried grease / crud and it just needed a good cleaning and lubrication. When I took it home I cleaned and slightly lubricated the necessary parts but the problem remained. It would open easily and swing out but slowed to a stop before fully swinging out. When I loosened the front screw, it would move freely. When I tightened the screw until it seated, the crane would bind. I tried switching the front and middle screws (not the flat rear screw) and it was the exact same result. I tried the search engine but only found trouble shooting related to unlocking the cylinder. Can anyone shed some light on this? Thanks so much.