- Joined

- Aug 21, 2005

- Messages

- 8,020

- Reaction score

- 7,101

Brand new Classic Line, Model 19-10, no lock, fresh from the Distributor.

Fit, finish, action, timing are all superior. I have not disassembled it.

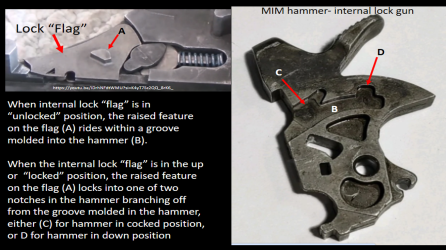

The hammer has a notch cut out on the left side when viewed from the rear. There appears to be an extra part that interacts with the hammer (no, it is not the bolt) and I cannot discern what its purpose is.

Has anyone noticed this? If so, what is the name of the part, and what is its purpose? I have been unable to find a thread about this, nor have I been able to locate a schematic for the new no-lock Model 19.

One picture shows it is a no-lock, one shows the "notch" cut out of the left side of the hammer, and two pictures shows it is the part about which I am asking.

Anyone know about this?

Fit, finish, action, timing are all superior. I have not disassembled it.

The hammer has a notch cut out on the left side when viewed from the rear. There appears to be an extra part that interacts with the hammer (no, it is not the bolt) and I cannot discern what its purpose is.

Has anyone noticed this? If so, what is the name of the part, and what is its purpose? I have been unable to find a thread about this, nor have I been able to locate a schematic for the new no-lock Model 19.

One picture shows it is a no-lock, one shows the "notch" cut out of the left side of the hammer, and two pictures shows it is the part about which I am asking.

Anyone know about this?