-

Forum Update: We've upgraded the software to improve security, performance, and the overall experience.

👉 Read why we made the change | Support the Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Picture of a cracked forcing cone on a model 65 or 66?

- Thread starter sgc

- Start date

Register to hide this ad

John Patrick

Member

- Joined

- Dec 2, 2021

- Messages

- 1,575

- Reaction score

- 2,465

I copied this one off Al Gore’s amazing internet.

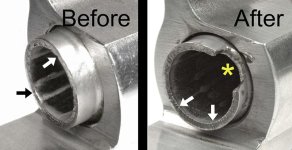

Cracked forcing cone and frame. Model 66 from the source. Did not give a - #.

ETA: Every photo I’ve seen of a cracked forcing cone, with or without a cracked frame, shows the crack at the corners of the milled flat on the bottom of the barrel extension.

Cracked forcing cone and frame. Model 66 from the source. Did not give a - #.

ETA: Every photo I’ve seen of a cracked forcing cone, with or without a cracked frame, shows the crack at the corners of the milled flat on the bottom of the barrel extension.

Attachments

Last edited:

K-22

Member

Based on the visible erosion, that forcing cone appears to have seen many hot loads.

����

����

austintexas

SWCA Member

The only cracked forcing cones I've seen were on M-15s (2), so It doesn't just happen with 357 magnums.

SWCA 892

SWCA 892

John Patrick

Member

- Joined

- Dec 2, 2021

- Messages

- 1,575

- Reaction score

- 2,465

- Joined

- Apr 21, 2021

- Messages

- 4,518

- Reaction score

- 7,666

Larger bullets help and don’t shoot .357’s every range trip unless one or two jacketed ones after shooting a bunch of lead bullets.

Saw a 66 4” few years ago at a local gun club swap meet that looked like a laser had cut forcing cone in half and many notches in the rest. Guy bought it anyway…

Saw a 66 4” few years ago at a local gun club swap meet that looked like a laser had cut forcing cone in half and many notches in the rest. Guy bought it anyway…

- Joined

- Apr 4, 2006

- Messages

- 19,307

- Reaction score

- 30,227

The rule of thumb for all J & K frame Magnums is to keep the magnum loads to a minimum and on the rare occasion they are shot - stick with 158 grain projectiles. That rule should preserve your J, K frame and prevent it from cracking or chipping.

Only S&W L & N Frames are truly designed for everyday sustained magnum use, IMO.

Only S&W L & N Frames are truly designed for everyday sustained magnum use, IMO.

Malysh

Member

Those are really depressing pictures!

Isn't it the 125 grain that gets the blame for this? The shorter bullet allows more hot gas to escape because it clears the cylinder sooner?

I don't know if I'm remembering right but I do know someone will quickly correct me if I'm not!

I don't know if I'm remembering right but I do know someone will quickly correct me if I'm not!

Protocall_Design

Vendor

The 125 gr. bullets and ball powder at high velocity are the 2 worst things for a forcing cone. The ball powder makes the little grooves all around that look like soil erosion.

Here’s an M65-8.

So the -8 didn't have the flat bottom forcing cone which was supposed to be the weak part?

pantannojack

US Veteran

My 19-2 has no flat spot, or not much of one. I read that when they changed the gas ring from the cylinder to the yoke (or other way around) it changed the diameter requiring more clearance. I picked this sample up just a few years ago, came in perfect blue condition either non fired new, or professionally rebuilt. I question the rings on the bbl stud face, and the look of bbl stud diameter.

Attachments

Isn't it the 125 grain that gets the blame for this? The shorter bullet allows more hot gas to escape because it clears the cylinder sooner?

I don't know if I'm remembering right but I do know someone will quickly correct me if I'm not!

The 110 gr shares equal blame but is not loaded as often.

4 in nickel 19.....Have shown this before. Cracked shooting 150 gr cast bullets and #2400 powder. Happened in 1986. I bought a barrel. Made frame blocks and changed it out myself. Hardest part of the change was getting the barrel cross pin out. Probably haven't shot it 10 times since.

Attachments

moonsterman

Member

- Joined

- Oct 6, 2023

- Messages

- 151

- Reaction score

- 158

Isn't it the 125 grain that gets the blame for this? The shorter bullet allows more hot gas to escape because it clears the cylinder sooner?

I don't know if I'm remembering right but I do know someone will quickly correct me if I'm not!

Your 100% spot on , the shorter bullet does not allow all the hot gases to be sealed off exposing the forcing cone to those still burning fakes of powder.

John Patrick

Member

- Joined

- Dec 2, 2021

- Messages

- 1,575

- Reaction score

- 2,465

So the -8 didn't have the flat bottom forcing cone which was supposed to be the weak part?

The flat is there, it’s just less obvious than in the previous photo.

It’s easier to see in the right hand photo of that second pair. Look for the thinner barrel extension, you should see the change in thickness.

The flat was originally as small as required to clear the gas ring on the cylinder.

When the gas ring was moved to the yoke the flat needed to be enlarged to clear that gas ring placement.

When the gas ring was moved back to the cylinder S&W didn’t return to the smaller milled flat, instead retaining the larger flat.

At least that’s what I’ve read on the issue. About Model 19-3 to 19-4 time frame, with some small flat and some large flat examples reportedly in both dashes.

If time allows today I’ll try to take some photos of my various older and (relatively) newer 357 K frames to highlight the difference. I have a 4” and two 2 1/2” M19s, a 4” and two 3” M13s, 4”, 3” and 2 1/ M66s, a 3” and three 4” M65s.

Thinking about it, the flats on 38spl K frames too, so I’ll look for the different flat sizes on my 38 K frames too. I have a 4” and three 3” M10s and a 3” M64.

Hopefully one or more example with the smaller flat and with the bigger flat (which most of my K frames should have.)

Last edited:

The only cracked forcing cones I've seen were on M-15s (2), so It doesn't just happen with 357 magnums.

SWCA 892

I'm glad to hear you say that. The only one I've ever seen was on a 15-8. I was starting to think I was nuts.

When I pointed it out to the gun shop guy, it disappeared into the back, never to be seen again.

Similar threads

- Replies

- 7

- Views

- 517

- Replies

- 3

- Views

- 237

- Replies

- 10

- Views

- 1K