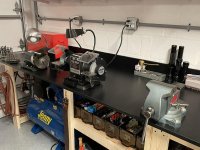

I am ordering a not expensive and hopefully sturdy 24"x 48" worktable with a "Rubberwood" top.

What vise should I get to attach to the table to keep a rifle secure when cleaning or tinkering.

Do I attach the vise to one end of the table and rest the muzzle on a shooting bag or do I get a vise for the middle of the table and the middle of the rifle.?

I have no plans for heavy torque such as removing or installing a barrel

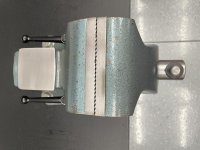

What sort of grip goes inside the jaws of the vise?

Thanks in advance

What vise should I get to attach to the table to keep a rifle secure when cleaning or tinkering.

Do I attach the vise to one end of the table and rest the muzzle on a shooting bag or do I get a vise for the middle of the table and the middle of the rifle.?

I have no plans for heavy torque such as removing or installing a barrel

What sort of grip goes inside the jaws of the vise?

Thanks in advance

Last edited: