This has always been a subject that I believe has been missed by

many but I have always been cognizant of it myself. I come from the corner of being a long time 10mm cartridge fan going back to the 1980's and it's not coincidence that "10mm guys" and ".40cal guys" had kind of knocked heads a bit.

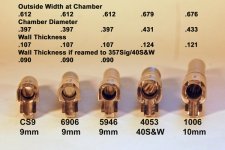

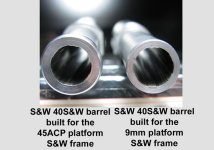

The first two successfully mass-produced .40cal guns on the market were the Glock 22 and the S&W 4006. In the case of both of these pistols, you (basically) had a 9mm sized frame running a 9mm sized slide and a 9mm sized barrel, but the barrel itself (bore and chamber) were opened up, metal removed, and necessarily larger holes left behind. The .40 S&W runs the same pressure as the 9mm (a hot round all on it's own at 35k psi) and it does all of this while being effectively shoe-horned in to a gun wholly designed around a smaller diameter cartridge & bullet of lower mass.

And in the completely opposite way in every possible direction...

The two offerings in 10mm from the same two gun makers were the Glock 20 and the 1006, and

both of these pistols took a gun of larger frame and larger slide with more mass, and a larger barrel with a larger bore and chamber and instead ran a

smaller diameter cartridge with a smaller diameter bullet of slightly lower mass.

So the 10mm pistols use the larger .45 frame and the larger, heavier .45 slide and the .45-sized barrel which now has MORE metal around both the chamber and bore than it does for the .45 ACP for which it was designed. It is worth noting that the max pressure expectation has been increased from the mid-range 21k psi of the .45 to the stout 37.5k psi max of the 10mm.

WHEW! All of the above for me to say that

yes, I have always been firmly of the camp that the .40 S&W designed pistols are running the ragged edge of what "should" have been done all the while sitting next to the 10mm pistols that show us easily and clearly exactly -HOW- it should have been done.

As I simply

refused to buy or own .40cal pistols in their heyday, I was only somewhat aware of the associated problems. I can say that while most all of us (at least all of us that were shooting and handloading in the early 1990's) know very very well about all the trouble Glock had with kabooms in the early generations of the Glock 22/23, I can't sit here and tell you that I was aware of a lot of S&W 40xx pistols doing the same thing.

But we should accept that it was more a "perfect storm" of both pistol design

AND cartridge design rather than simply the pistols themselves. There exists precious small room for error in the .40 S&W cartridge, especially for handloaders, and in my (experienced) opinion, the most likely genuine culprit in .40 S&W reload "disaster" has been exactly the

unintended and wholly unnoticed occurrence of bullet setback in the case.

My argument: the .40 S&W cartridge leaves -NO- room for error and when the bullet gets accidentally and unknowingly pushed deeper in to the cartridge case and discharged, the pressure rockets to an alarming level and catastrophe (or near catastrophe) happens -AND- (and this is a very import part of my argument!), the evidence is instantly

ERASED and it's not quite so easy to see or understand

WHY it happened.

You will never see the bullet setback and the greatly reduced combustion space in the aftermath of a .40cal over pressure event.

These days... I actually do make .40cal ammo at my bench. It took me YEARS to get on board with the idea. I run .40 in only two handguns these days... a very late model 4006 and my Glock 29 (10mm) running a KKM .40 S&W barrel.

I believe there are ways to mitigate the inherent minefield of the .40cal cartridge at the load bench, and I keep those in mind when I make my ammo.

Sincere apologies for the length of my post.