Anyway, CLP is what we called it. LSA was also known by a less polite name having to do with simians. More or less official, back in the day...

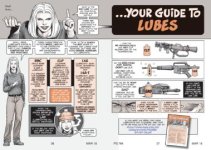

https://www.logsa.army.mil/psmag/archives/PS2018/784/784-36-37.pdf

https://www.logsa.army.mil/psmag/archives/PS2008/671/671-23.pdf

https://www.logsa.army.mil/psmag/archives/PS2018/784/784-36-37.pdf

https://www.logsa.army.mil/psmag/archives/PS2008/671/671-23.pdf