Hi everybody,

I know this question has been asked more than once, if QuickLoad is accurate enough or not.

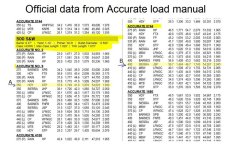

Well I got finally a copy on my PC and I ran some tests comparing the official data found on Accurate website with QL simulation.

Either I have done something stupidly wrong or how do we explain these huge differences?

I mean check the images attached/below: loads are for the 500 SW Magnum:

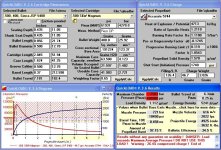

Load 1 HDY 350 grs, 41.8 grs of AA#9, Accurate says 55.000 PSI and 1878 fps Quickload says 90.000 PSI and 2000 fps!!

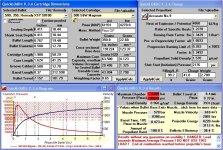

Load 2 SIE 400 grs, 46.7 grs of AA5744, Accurate says 54.000 PSI and 1743 fps Quickload says 110.000 PSI and 2020 fps and also 26% of compression!

How is this possible?

I mean, OK, QuickLoad should NEVER be used to develop a Load, but at this point it makes me wonder if it has reasonable information in it at all, to compare burn%, pressures etc etc...

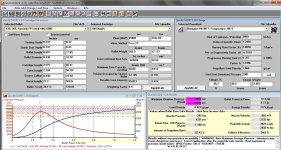

The data I input seems correct, all taken straight from the QL pre-set data, I just edited the COL and the Amount of powder...

Thanks

Andy

I know this question has been asked more than once, if QuickLoad is accurate enough or not.

Well I got finally a copy on my PC and I ran some tests comparing the official data found on Accurate website with QL simulation.

Either I have done something stupidly wrong or how do we explain these huge differences?

I mean check the images attached/below: loads are for the 500 SW Magnum:

Load 1 HDY 350 grs, 41.8 grs of AA#9, Accurate says 55.000 PSI and 1878 fps Quickload says 90.000 PSI and 2000 fps!!

Load 2 SIE 400 grs, 46.7 grs of AA5744, Accurate says 54.000 PSI and 1743 fps Quickload says 110.000 PSI and 2020 fps and also 26% of compression!

How is this possible?

I mean, OK, QuickLoad should NEVER be used to develop a Load, but at this point it makes me wonder if it has reasonable information in it at all, to compare burn%, pressures etc etc...

The data I input seems correct, all taken straight from the QL pre-set data, I just edited the COL and the Amount of powder...

Thanks

Andy