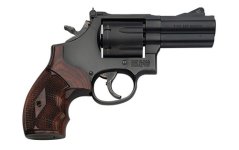

There is another thread that talks about whether Smiths or Rugers are stronger, more durable or more reliable. I have a few of each and do not criticize either company. Neither is perfect but I like their guns. The average age of my Smiths is a lot older and I treat my old Smiths carefully. My 1980's N frame, my GP-100 and my Bisley 44 mag are for the big stuff. I have worked in reliability for years and I thought I would ramble about it. Here goes:

Durability, Reliability and Strength (as used in the automotive, locomotive and aerospace industries)

Reliability means the ability to perform the intended function with no interruption. It is generally defined by mean time between failures (MTBF). The failures may be acceptable or completely unacceptable. An acceptable failure is a light bulb burning out in a location that has multiple light bulbs all providing light. An unacceptable failure would be a wheel bearing failure on an automobile. The ability to fail in a soft manner removes a component from the reliability of the system. Thus one headlight burning out is not a "failure mode" for an automobile – the automobile will still get you home.

Locomotives usually have one engine and six drive motors (one per axle). One drive motor can fail in a manner which causes that set of wheels to stop pulling, resulting in a small decrease in traction. The drive motor could also fail in a manner that locks the axle, stopping the entire train. The engine can also fail, causing that specific locomotive to stop pulling, but the train might include one, two, three or more locomotives. It is easy to see that these different failure modes have vastly different consequences. In the locomotive world "failures per locomotive year" measures events in which the locomotive stops pulling, but does not stop the train. "Mission aborts" measures events in which a locomotive stops the entire train from moving.

A "reliable" component may not fail but might still require lots of expensive inspections or planned maintenance. A "reliable" component may have a useful life that is very short. Consumers do not generally tolerate this. Consumers do tolerate this sometimes (light bulbs, engine oil, guitar strings, chicken with "sell by" dates) but they do not tolerate required replacement in very many other areas.

Durability means the ability to resist the need for maintenance or repair. This includes planned maintenance and unexpected repair. A headlight bulb that burns out every month would not affect the operation of the car (reliability) but would be an irritation none the less due to low durability. A galvanized fence post is very durable and should require little or no maintenance during life due to normal use. A more durable system (engine, furnace, airplane, handgun) requires less frequent maintenance and repairs. Planned maintenance can be used to manage reliability – oil changes and tooth cleaning sessions are planned in order to minimize unexpected repairs. If two engines rarely fail but one engine requires more frequent overhauls to achieve that then that engine is the less durable of the two, even with equal reliability.

Consumers display different levels of tolerance for proactive maintenance for different products. Engine rebuilds during the life of a car were expected during the early twentieth century but are considered a sign of poor design now. Regular health checkups for humans are are accepted as the norm. Semiautomatic pistol owners accept a large amount of disassembly for (required) cleaning of the product, television owners would not accept the same level of disassembly and/or cleaning.

Strength or damage resistance relates to resistance to catastrophic failure under unexpected (or rarely expected) loads. Stand on your kitchen chair to reach something in a high cabinet. Does it break? What if an extremely overweight person stands on an antique French Provincial chair? Does it break? Do you become upset with the manufacturer in either case? We'd expect the galvanized fence post mentioned before to last 40 to 100 years with no maintenance, but no one would be unhappy with the manufacturer of that fence post if a car jumped the curb and destroyed it. Guardrails on bridges are meant to contain cars but fence posts are not.

Let us consider "Joe", an avid bullseye competitor. He competes in a club match every week. He shoots two targets in slow fire, two targets in timed fire and two targets in rapid fire with his customized 1911. He religiously disassembles and cleans his gun after each match. Joe has accepted a huge maintenance burden. He is cleaning his gun every 60 shots! Joe's gun never jams or misfires during the entire season. Is his gun reliable? Yes, it is 100% reliable. But Joe's actions betray his fear – that the gun may not be reliable enough for 100 shots without a failure. His reliability demands are so high that he treats his gun as if the average time between failures is less than 100 shots. Joe's gun may wear out from cleaning before it wears out from shooting. Joe may believe his Kimber (or Colt or whatever) under the ministrations of his custom builder, is more reliable than the other guy's gun. But if the other guy's gun also never fails no one will ever know.

Reliability - The average revolver shooter would really love to see someone buy three or four of each gun and shoot 100,000 rounds through each of them, with reasonable cleaning, then report on any parts that broke or wore excessively This would get us some true reliability numbers – mean number of shots before something bad enough to stop the gun from firing happened. Do this with a mix of light and hot loads. No one I know has the time or money to do this. Smith does have some very pretty 100-year-old guns that still work, Ruger cannot match that. Smith also has a lot of old guns that have failed – we can blame that on abuse if we like and it is likely true. But all we know today is that some 100-year-old Smiths still work and some 50 plus-year-old Rugers still work and if we take care of our guns we expect they will last even longer.

Now consider Bubba, who always loads his revolvers hot. He uses the loading manuals' max loads as his starting point and brags that his Smith, or Ruger, loves these hot loads. He may have never blown up a gun. If he does blow up a gun it will prove nothing. The gun, whether Smith or Ruger, failed at some hidden weak point. I am not accusing either company of shipping junk, but all metal has local points that are weaker than average. Voids, contamination, sharp tool marks, no gun can possibly be free from these. Bubba's handloads are not uniformly charged or seated or crimped. The outside temperature is not constant. The hardness of the lead and copper in his bullets is not uniform. One day the right combination (perfect storm) of all these factors make Bubba's gun go "Boom." This relates to strength, and thick walls help. Forgings generally help as well but castings can be incredibly strong if you spend enough time and money on them. I promise you that Ruger and Smith both put enough extra into their guns to ensure that most of the Bubbas out there do not blow themselves up, at least the first time, whether the gun's frame is a casting or forging.

The previous paragraph is about strength. To test it you could take several of each gun and shoot hotter and hotter loads until they failed. In the aviation business we try to ensure that things fail "gracefully" which means that they show visible indications of failure before they just fly to pieces. The revolver industry seems unable to accomplish this. I am not blaming them – aircraft owners do not mix up their own home-brew fuels in the basement. But the real point is that to determine if Smith or Ruger is stronger you would need to blow a few up and see which ones went up at lower overloads. This might be fun but it is probably pointless. We have loading manuals for a reason.

Maybe this will stimulate some more discussion.

Durability, Reliability and Strength (as used in the automotive, locomotive and aerospace industries)

Reliability means the ability to perform the intended function with no interruption. It is generally defined by mean time between failures (MTBF). The failures may be acceptable or completely unacceptable. An acceptable failure is a light bulb burning out in a location that has multiple light bulbs all providing light. An unacceptable failure would be a wheel bearing failure on an automobile. The ability to fail in a soft manner removes a component from the reliability of the system. Thus one headlight burning out is not a "failure mode" for an automobile – the automobile will still get you home.

Locomotives usually have one engine and six drive motors (one per axle). One drive motor can fail in a manner which causes that set of wheels to stop pulling, resulting in a small decrease in traction. The drive motor could also fail in a manner that locks the axle, stopping the entire train. The engine can also fail, causing that specific locomotive to stop pulling, but the train might include one, two, three or more locomotives. It is easy to see that these different failure modes have vastly different consequences. In the locomotive world "failures per locomotive year" measures events in which the locomotive stops pulling, but does not stop the train. "Mission aborts" measures events in which a locomotive stops the entire train from moving.

A "reliable" component may not fail but might still require lots of expensive inspections or planned maintenance. A "reliable" component may have a useful life that is very short. Consumers do not generally tolerate this. Consumers do tolerate this sometimes (light bulbs, engine oil, guitar strings, chicken with "sell by" dates) but they do not tolerate required replacement in very many other areas.

Durability means the ability to resist the need for maintenance or repair. This includes planned maintenance and unexpected repair. A headlight bulb that burns out every month would not affect the operation of the car (reliability) but would be an irritation none the less due to low durability. A galvanized fence post is very durable and should require little or no maintenance during life due to normal use. A more durable system (engine, furnace, airplane, handgun) requires less frequent maintenance and repairs. Planned maintenance can be used to manage reliability – oil changes and tooth cleaning sessions are planned in order to minimize unexpected repairs. If two engines rarely fail but one engine requires more frequent overhauls to achieve that then that engine is the less durable of the two, even with equal reliability.

Consumers display different levels of tolerance for proactive maintenance for different products. Engine rebuilds during the life of a car were expected during the early twentieth century but are considered a sign of poor design now. Regular health checkups for humans are are accepted as the norm. Semiautomatic pistol owners accept a large amount of disassembly for (required) cleaning of the product, television owners would not accept the same level of disassembly and/or cleaning.

Strength or damage resistance relates to resistance to catastrophic failure under unexpected (or rarely expected) loads. Stand on your kitchen chair to reach something in a high cabinet. Does it break? What if an extremely overweight person stands on an antique French Provincial chair? Does it break? Do you become upset with the manufacturer in either case? We'd expect the galvanized fence post mentioned before to last 40 to 100 years with no maintenance, but no one would be unhappy with the manufacturer of that fence post if a car jumped the curb and destroyed it. Guardrails on bridges are meant to contain cars but fence posts are not.

Let us consider "Joe", an avid bullseye competitor. He competes in a club match every week. He shoots two targets in slow fire, two targets in timed fire and two targets in rapid fire with his customized 1911. He religiously disassembles and cleans his gun after each match. Joe has accepted a huge maintenance burden. He is cleaning his gun every 60 shots! Joe's gun never jams or misfires during the entire season. Is his gun reliable? Yes, it is 100% reliable. But Joe's actions betray his fear – that the gun may not be reliable enough for 100 shots without a failure. His reliability demands are so high that he treats his gun as if the average time between failures is less than 100 shots. Joe's gun may wear out from cleaning before it wears out from shooting. Joe may believe his Kimber (or Colt or whatever) under the ministrations of his custom builder, is more reliable than the other guy's gun. But if the other guy's gun also never fails no one will ever know.

Reliability - The average revolver shooter would really love to see someone buy three or four of each gun and shoot 100,000 rounds through each of them, with reasonable cleaning, then report on any parts that broke or wore excessively This would get us some true reliability numbers – mean number of shots before something bad enough to stop the gun from firing happened. Do this with a mix of light and hot loads. No one I know has the time or money to do this. Smith does have some very pretty 100-year-old guns that still work, Ruger cannot match that. Smith also has a lot of old guns that have failed – we can blame that on abuse if we like and it is likely true. But all we know today is that some 100-year-old Smiths still work and some 50 plus-year-old Rugers still work and if we take care of our guns we expect they will last even longer.

Now consider Bubba, who always loads his revolvers hot. He uses the loading manuals' max loads as his starting point and brags that his Smith, or Ruger, loves these hot loads. He may have never blown up a gun. If he does blow up a gun it will prove nothing. The gun, whether Smith or Ruger, failed at some hidden weak point. I am not accusing either company of shipping junk, but all metal has local points that are weaker than average. Voids, contamination, sharp tool marks, no gun can possibly be free from these. Bubba's handloads are not uniformly charged or seated or crimped. The outside temperature is not constant. The hardness of the lead and copper in his bullets is not uniform. One day the right combination (perfect storm) of all these factors make Bubba's gun go "Boom." This relates to strength, and thick walls help. Forgings generally help as well but castings can be incredibly strong if you spend enough time and money on them. I promise you that Ruger and Smith both put enough extra into their guns to ensure that most of the Bubbas out there do not blow themselves up, at least the first time, whether the gun's frame is a casting or forging.

The previous paragraph is about strength. To test it you could take several of each gun and shoot hotter and hotter loads until they failed. In the aviation business we try to ensure that things fail "gracefully" which means that they show visible indications of failure before they just fly to pieces. The revolver industry seems unable to accomplish this. I am not blaming them – aircraft owners do not mix up their own home-brew fuels in the basement. But the real point is that to determine if Smith or Ruger is stronger you would need to blow a few up and see which ones went up at lower overloads. This might be fun but it is probably pointless. We have loading manuals for a reason.

Maybe this will stimulate some more discussion.

Last edited: