sigp220.45

US Veteran

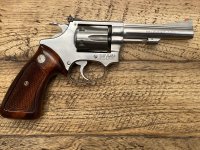

I've owned 5 K-frame .22 revolvers. A pre-17, a Model 17, and two Model 18s. I hated them all.

Each of them was hard to load, and nearly impossible to reload. Until I started to bring a rubber mallet to the range I had an ejector rod shaped bruise on my left palm from trying to just get the empties out so I could fight to get more rounds in.

I swore off.

One day, I had the chance to buy a K-22 and K-38 from the same era, treasured heirlooms from a deceased PawPaw, traded in for 500 bucks credit towards a Glock 43X with a red dot. I got them both for 450 each.

The K-38 was as expected - perfect.

The K-22? Also perfect!

I had it at the range today - easy in, easy out, nice little groups at the length of the indoor range. The guy in the next lane stuck his head around and said - S***, I thought you were shooting a rifle!

No more for me, this one is it.

Each of them was hard to load, and nearly impossible to reload. Until I started to bring a rubber mallet to the range I had an ejector rod shaped bruise on my left palm from trying to just get the empties out so I could fight to get more rounds in.

I swore off.

One day, I had the chance to buy a K-22 and K-38 from the same era, treasured heirlooms from a deceased PawPaw, traded in for 500 bucks credit towards a Glock 43X with a red dot. I got them both for 450 each.

The K-38 was as expected - perfect.

The K-22? Also perfect!

I had it at the range today - easy in, easy out, nice little groups at the length of the indoor range. The guy in the next lane stuck his head around and said - S***, I thought you were shooting a rifle!

No more for me, this one is it.