Here's the deal.

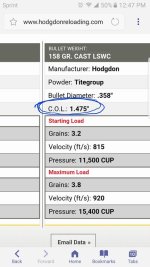

If the load data says something like "158-grain lead bullet", then the OAL they list is without context. It tells you what the OAL of the cartridge they loaded was, but we really have no idea what the bullet design was. In that situation, the OAL is utterly useless.

But suppose it says "158-grain LSWC"? Same issue. There are

tons of different bullet designs for each weight and profile. You can have wildly different bullet lengths, with identical weights, simply because the two bullets have different ogives.

If I'm reading your posts correctly, you fall into this second category. You're using a 158-grain jacketed RNFP from Xtreme, but the listed data is for the Hornady XTP. Even though the bullets are of the same construction, weigh the same, and are of the same general design, they're unlikely to be identical dimensionally.

The only situation in which OAL data is truly useful is if they specific mold of the bullet, and you're also using that exact design. For instance, if you were looking through your Lyman manual and found data for a 158-grain LSWC #1234567, and you also happened to be using bullets poured from a #1234567 mold.

But...not always.

Sometimes, the manualmakers will pick an OAL almost arbitrarily, and intentionally seat the bullet deeper than normal. For instance, they might seat the bullet up to the shoulder. In which case, they list the "minimum OAL" as that--the shortest OAL they tested.

The bulletmaker didn't simply place the cannelure at the top of the bearing surface, or pick it at random. The placed it such that if you seat to that depth and crimp there, the amount of case volume occupied by the bullet will be no more than what was tested in load data.