Hi guys! I'm a mid to advanced level tinkerer, have been fixing things including cars for over 30 years, and am planning on trying to improve triggers, and possibly lockup and timing, on various personal guns to include S&W J, K, and L frames, as well as Ruger SP and GP, and maybe even troubleshooting an older Python.

The objective of this post is to ask for recommendations on specialized tools for working on the above; things like files, stones, and whatever else that's required. I already have the screwdriver with a multitude of bits, Dremel tool with a bunch of accessories, trigger scale, pliers, picks, cleaning rods with proper jags, brushes, cleaners, oils, polishing and buffing compounds, etc. It doesn't have to be the absolute best professional tool, but I rather buy only once.

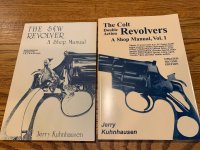

I've created another thread asking for suggestions on good written sources for performing the above-mentioned gunsmithing work.

If you have any suggestions for good quality gunsmithing tools, please list below.

Thanks in advance!

The objective of this post is to ask for recommendations on specialized tools for working on the above; things like files, stones, and whatever else that's required. I already have the screwdriver with a multitude of bits, Dremel tool with a bunch of accessories, trigger scale, pliers, picks, cleaning rods with proper jags, brushes, cleaners, oils, polishing and buffing compounds, etc. It doesn't have to be the absolute best professional tool, but I rather buy only once.

I've created another thread asking for suggestions on good written sources for performing the above-mentioned gunsmithing work.

If you have any suggestions for good quality gunsmithing tools, please list below.

Thanks in advance!