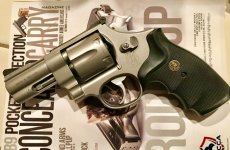

I've decided I want to pursue the dream of building a 625 .45ACP snubnose. The failed 625-10 would be a great example if the guns hadn't had so many problems (cracked yokes and frames, guns blowing up), so I'm thinking of making a version with a steel frame and yoke. I have a 625-2 that would serve as the basis of the conversion (and the 3-inch 625-2 is close to what I envision although I'd like a barrel without underlug). I can think of three possible approaches:

1. Find a gunsmith to cut down the barrel of my 625-2 (probably trimming it even with the end of the ejector rod lug).

2. Find a gunsmith to install a 625-10 barrel on my existing 625-2. (Barrels still available from Numrich.) This creates some problems since the 625-10 has fixed sights and a new front sight would have to be constructed, and a lock would have to be added to the yoke since the 625-10 barrel doesn't have a lock for the end of the ejector rod. Two members of the forum have written about attempting this conversion but they haven't been on the forum in quite a while and don't respond to messages, so they're probably gone, and aren't available to answer questions.

3. Find a gunsmith to make and install a new snubby barrel for the 625 from barrel stock. I believe Hamilton Bowen used to do this but he no longer works on S&W double-actions.

Any recommendations for which of these ideas might be most practical? And, any suggestions for a gunsmith to do the work? I've contacted a couple of gunsmiths in my part of the country; one wasn't interested in trying and one wanted $1800 to do the conversion I mention as #1 above. I'm not thinking I want a conversion that costly, but maybe I'm being too cheap?

Or maybe I should just find a 3-inch 625 and say "Good enough...."

Your suggestions appreciated.

Thanks,

Whisper

1. Find a gunsmith to cut down the barrel of my 625-2 (probably trimming it even with the end of the ejector rod lug).

2. Find a gunsmith to install a 625-10 barrel on my existing 625-2. (Barrels still available from Numrich.) This creates some problems since the 625-10 has fixed sights and a new front sight would have to be constructed, and a lock would have to be added to the yoke since the 625-10 barrel doesn't have a lock for the end of the ejector rod. Two members of the forum have written about attempting this conversion but they haven't been on the forum in quite a while and don't respond to messages, so they're probably gone, and aren't available to answer questions.

3. Find a gunsmith to make and install a new snubby barrel for the 625 from barrel stock. I believe Hamilton Bowen used to do this but he no longer works on S&W double-actions.

Any recommendations for which of these ideas might be most practical? And, any suggestions for a gunsmith to do the work? I've contacted a couple of gunsmiths in my part of the country; one wasn't interested in trying and one wanted $1800 to do the conversion I mention as #1 above. I'm not thinking I want a conversion that costly, but maybe I'm being too cheap?

Or maybe I should just find a 3-inch 625 and say "Good enough...."

Your suggestions appreciated.

Thanks,

Whisper

Last edited: