I purchased my first revolver a while back, a model 627 Performance center in .357 and I've had some issues that I'd like some advise on.

It started showing quite quickly when I was shooting some LWC 38sp and they started to tumble, that's when I noticed that there was a lot of lead in the barrel.

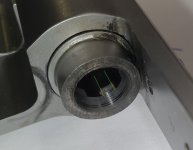

After cleaning and inspecting it I found that the forcing cone looked really rough and and seem to have done a bad chamfer cut of the rifling at the throat. As seen in the picture it has left a "lump" on the side of the chamfer of each rifling. And as seen the lead build up directly after the lumps also.

After contact with my store it was sent in for a check and the forcing cone was recut, but to me the issue is still there. It's possible to feel the lump at the start of the rifling.

What is you opinion, is this normal on the forcing cones?

Do you think my issue with excessive lead buildup could come from this issue so I should contact them again?

The barrel itself also have these traverse marks in the barrel but S&W insists that they are normal toolmarks from the new process and do not affect precision. But they do grab a lot of copper..

It started showing quite quickly when I was shooting some LWC 38sp and they started to tumble, that's when I noticed that there was a lot of lead in the barrel.

After cleaning and inspecting it I found that the forcing cone looked really rough and and seem to have done a bad chamfer cut of the rifling at the throat. As seen in the picture it has left a "lump" on the side of the chamfer of each rifling. And as seen the lead build up directly after the lumps also.

After contact with my store it was sent in for a check and the forcing cone was recut, but to me the issue is still there. It's possible to feel the lump at the start of the rifling.

What is you opinion, is this normal on the forcing cones?

Do you think my issue with excessive lead buildup could come from this issue so I should contact them again?

The barrel itself also have these traverse marks in the barrel but S&W insists that they are normal toolmarks from the new process and do not affect precision. But they do grab a lot of copper..