Lubricants

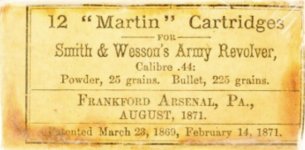

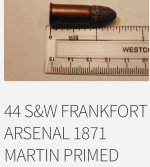

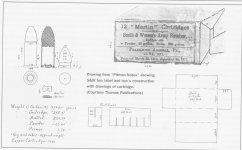

Even early reloading kits that date to 1871 came with written instructions that included the use of bullet lubricants.

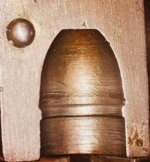

The earliest kits the instructions were written on the pasteboard lid and recommended the use of Callow, Lard, animal fat to lubricate bullets.

Canned Lard was very common and in use when cartridge pistols were introduced so it was readily Available for reloading even in the 1870's at remote locations.

So basically bullet lubricants and their required use was common knowledge back then.

You watch some of these modern videos on using reloading tools etc and they often forget to include the bullet lube. A leaded up bore/ forcing cone is the result.

Murph

Even early reloading kits that date to 1871 came with written instructions that included the use of bullet lubricants.

The earliest kits the instructions were written on the pasteboard lid and recommended the use of Callow, Lard, animal fat to lubricate bullets.

Canned Lard was very common and in use when cartridge pistols were introduced so it was readily Available for reloading even in the 1870's at remote locations.

So basically bullet lubricants and their required use was common knowledge back then.

You watch some of these modern videos on using reloading tools etc and they often forget to include the bullet lube. A leaded up bore/ forcing cone is the result.

Murph

Last edited: