You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crimp jump?

- Thread starter S.B.

- Start date

Register to hide this ad

ArchAngelCD

Moderator, SWCA Member, Absent Comrade

I never tried that. I just push the round into the bench and if it holds it's good.

I can't say I've had any problems with bullets walking but occasionally I'll check like ArchAngelCD. push against the bench. I don't lay on the cartridge, just a firm push...

Long ago when I had a case "Magnumitis" I checked some on my 44 Mag full power loads (Max loads of WC 820 under a 250 gr LSWC) by firing 5 rounds then measuring the OAL of the 6th. Never had any rounds "grow"...

Long ago when I had a case "Magnumitis" I checked some on my 44 Mag full power loads (Max loads of WC 820 under a 250 gr LSWC) by firing 5 rounds then measuring the OAL of the 6th. Never had any rounds "grow"...

Last edited:

I just test for possible setback on the bench. Either it slips back into the case with reasonable pressure or it doesn't. I geek out on many other reloading steps, but I don't get too technical on this aspect.

For me, incorrectly sized bullets have been the only issue. It was pretty obvious.

For me, incorrectly sized bullets have been the only issue. It was pretty obvious.

__steve__

Member

Just had some roll-crimped bullets jump the cannelure the other day. They were some cast Missouri 400gr 500mag loaded to a honest maximum level.

Still quite new with the loading process, but I thought I had put a hefty crimp on them. Now I know they weren't.

The press into scale idea sounds good, but it seems that having the force in the wrong direction might not have the same hold of static friction as with the direction during recoil

Still quite new with the loading process, but I thought I had put a hefty crimp on them. Now I know they weren't.

The press into scale idea sounds good, but it seems that having the force in the wrong direction might not have the same hold of static friction as with the direction during recoil

Last edited:

Most crimps will behave if they are not in a full load.

The case condition plays a lot on how the crimp will hold.

Its grip will decrease if the inside of the case hase been milled or

if the bullet is soft lead or a copper bullet that has a very light "can" from the factory.

I also agree on the light push on the reloading table if I find bad loads but my dies have been set correctly

with a "Dummy load" that solves this problem, so far.

Good loading.

The case condition plays a lot on how the crimp will hold.

Its grip will decrease if the inside of the case hase been milled or

if the bullet is soft lead or a copper bullet that has a very light "can" from the factory.

I also agree on the light push on the reloading table if I find bad loads but my dies have been set correctly

with a "Dummy load" that solves this problem, so far.

Good loading.

twodog max

Member

I have only had one problem with crimp jumping in 50 years of reloading. I was loading 348 Winchester in a Model 71. I could not roll crimp enough. I called RCBS, back when humans worked there, talked to a guy he sent me a smaller expander ball and problem was solved. I load a lot for lever guns up to 45/70 level and magnum pistol with no other problems.

ArchAngelCD

Moderator, SWCA Member, Absent Comrade

The trick is proper neck tension. Sometimes applying excessive crimp will actually loosen the bullet so first be sure the case is properly sized before you apply the crimp.

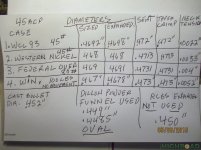

5.56 is 35 lbs minimum. 45 acp can run 45 to over 100 lbs to move a bullet.

Measure outside diameter (OD) in neck area, before & after seating a bullet. After seating, OD should be .002" larger as a minimum. For auto .003" For 460 S&W .004"

Measure outside diameter (OD) in neck area, before & after seating a bullet. After seating, OD should be .002" larger as a minimum. For auto .003" For 460 S&W .004"

Last edited:

Arc Angel

Member

Years ago I read that using a bathroom scale(pushing the bullets into the scale) to prevent crimp jump was a good indicator for reloading. Could someone here refresh my memory as to just how many pounds this is please?

Steve

Here's something that I wrote for someone the other day:

With regard to 9x19mm cartridges that are intended for use in a semiautomatic pistol, all ya gotta do is to simply tighten up that 9x19mm taper crimp until it is sufficient to hold the bullet in place.

Do NOT 'over-squeeze' the cartridge; or, almost paradoxically, you'll actually loosen the case mouth. Once a taper crimp takes effect leave it at its lightest mechanical setting.

On reloads I used to look for a little, ‘fairy dust’ from the slightly elongated (straight wall) pistol brass after running a dozen or so rounds through the crimping die. (Whether I was using a taper, or a roll crimp this usually told me that the crimping die was performing well.)

Do NOT use a roll crimp (revolver) die on 9mm cartridges that are intended to be used in a semiautomatic action. All you’ll be doing is creating a semi-auto headspace problem for yourself.

I am no longer reloading; but, when I did, I used 9mm RCBS and Dillon taper-crimp dies. In more than 40 years of reloading I, perhaps only once, had a reloaded bullet, ‘walk’. (Crappy thin-wall commercial ammo like Blazers can, ‘walk’ on you at any time.)

Here's a useful little expedient test for pistol cartridges to keep in mind: Take a few finished cartridges and push them nose down onto a bathroom scale. You should be able to push down on these bullets up to as much as 25–30 lb without experiencing any bullet setback.

If a 9mm bullet sets back into the case before reaching 25 lb then the crimp setting on the die is either too light, or the cartridge has been 'over-squeezed'.

gwpercle

Member

Never heard of the bathroom scales pounds test .

Like ArchAngel in post #2 , we were taught to press the bullet into the edge of the reloading bench ... firmly (not Magilla Gorilla ) or hold the round in your hand with fingers and apply thumb pressure to bullet .

If they hold ... you good !

No bathroom scale required,

Gary

Like ArchAngel in post #2 , we were taught to press the bullet into the edge of the reloading bench ... firmly (not Magilla Gorilla ) or hold the round in your hand with fingers and apply thumb pressure to bullet .

If they hold ... you good !

No bathroom scale required,

Gary

Similar threads

- Replies

- 17

- Views

- 813