I have owned my 686 4" since 1986 and have nothing but praise for the workmanship/milling that S&W put into their guns back then. HOWEVER...

That said, I just bought a new 642CT and found the quality was

NOT what I expected. After shooting 50 rounds at the range and running caps for 200-300 rounds, I started getting a pronounced catch/lock on the trigger pull of this "brand new" revolver.

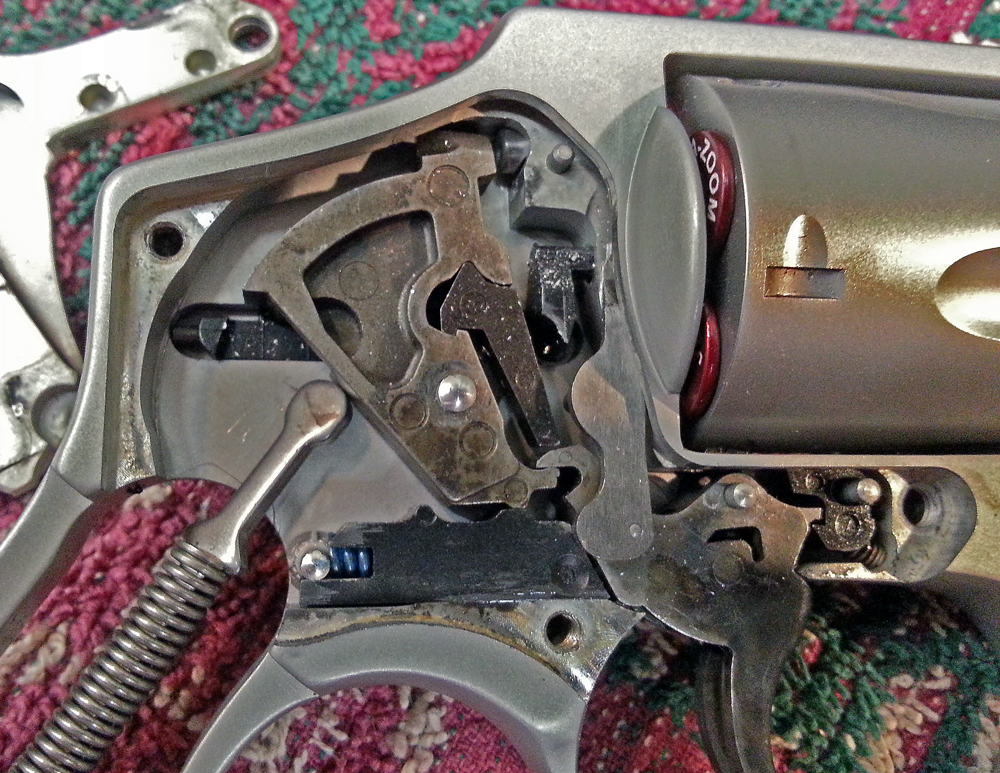

HOWEVER, being rather anal, I immediately decided to pull this "brand new" 642CT apart to find out what was going on. As you can see in the image below, there are plenty of shavings to go around. On closer inspection I found much in the way of rough edges on both milled and cast parts, but mostly on the cast pieces.

The Thumb activator/release cast piece had actually started to gouge the back of the frame's channel because of the castings elevated rough edges. Took some 600grit and a small rat-tail file and cleaned/smoothed some of the edges on the thumb release mechanism that was digging into the frame. Also cleaned up the trigger mechanism's working edges where I could see how the wear pattern was developing.

After the cleaning/fitting, I lubed everything with a touch of CLP. I think this did much more for ease of use than wearing out my finger snapping all those caps...

NOTE: If you look closely at the aft end of the thumb release, you can clearly see some of the casting edges standing proud. The backside of this piece had the same and was actively gouging the aluminum frame. Remember that I have had this gun less than one week.