Lou_the_welder

Member

Hello all!

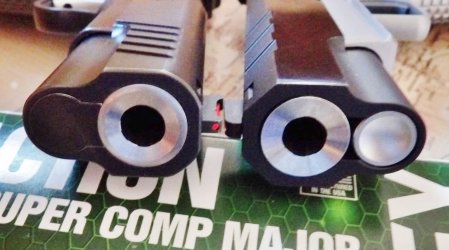

How do you reassemble a 1911 slide when the barrel has no barrel bushing- with a two piece guide rod. That is the question.

The way I do it, is unscrew the guide rod. Remove the slide stop. Pull out the slide from the frame, holding the slide with my hand. Slowly let go of the spring and bottom part of the guide rod - then pull the barrel forward.

The way I assemble- i think has always been wrong. Since this setup is not a conventional type 1911 barrel with bushing.

I install the barrel. Put that tube in before the spring. Push the spring in with the bottom part of the guide rod. Hold it in with my hand. Tighten the rest of the two piece guide rod, hand tight. Slide in the frame. Install slide stop. Tighten guide rod with allen wrench. And that's it.

Is this it? Is there any easier way? What say ye'

How do you reassemble a 1911 slide when the barrel has no barrel bushing- with a two piece guide rod. That is the question.

The way I do it, is unscrew the guide rod. Remove the slide stop. Pull out the slide from the frame, holding the slide with my hand. Slowly let go of the spring and bottom part of the guide rod - then pull the barrel forward.

The way I assemble- i think has always been wrong. Since this setup is not a conventional type 1911 barrel with bushing.

I install the barrel. Put that tube in before the spring. Push the spring in with the bottom part of the guide rod. Hold it in with my hand. Tighten the rest of the two piece guide rod, hand tight. Slide in the frame. Install slide stop. Tighten guide rod with allen wrench. And that's it.

Is this it? Is there any easier way? What say ye'

Attachments

Last edited: