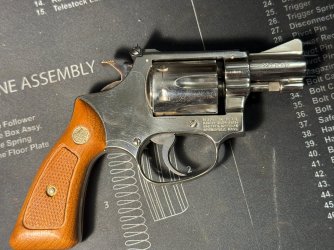

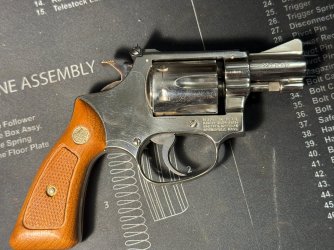

The extra FP strikes on the face of the cylinder are from the cylinder skipping passed it's intended locked position when the revolver is cocked. The cylinder misses being locked and skips passed the position slighty leaving the space betw the intended cartridge to be fired and the next up cart as the area that is struck by the firing pin when the hammer falls.

This usually happens when the cylinder is rotated quickly and has a lot of momentum speed. It can happen in either SA or DA mode if the action is cocked very quickly and the cylinder is given that HS momentum.

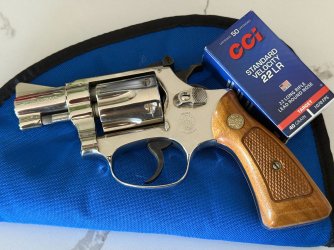

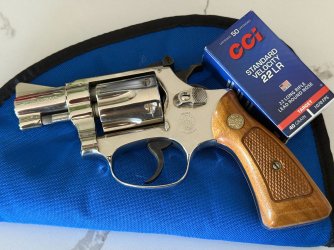

It happens more so on the heavier frame guns and heavy calibers where there is more weight and size involved. But I've seen it on the J frame .22's as well.

I had an otherwise nice Model 35 that the back side of the cylinder was tattooed w/o mercy betw the chambers from this.

Some of your 'misfires' may actually be when the cylinder is skipping by a cartridge and landing in a position betw the chambers. The hammer fall places the FP into the blank area of the cylinder betw the chambers and you hear the 'click'

You assume the click was upon a cartridge and it was a misfire.

But it could be it wasn't striking the cart at all and was just the click of the FP striking the steel area betw the chambers.

Or a combination of issues like the above plus,,a weak main spring,,a firing pin spring and FP that is loaded up with dried oil/crud slowing down the FP motion,,crud under the extractor cushioning the FP strike.

Excess headspace can cause it as well.

With todays less than Steller spec .22 ammo, I wouldn't be surprised to see

some with under spec rim thicknesses causing that problem in a gun chamber that measures perfectly.