New or old, Unique is the same as ever, and one of the best possible powder choices for lead bullets in a .357 Magnum, or almost any handgun caliber. I have no idea why Lyman does not list data for the .357 in their newer manuals.

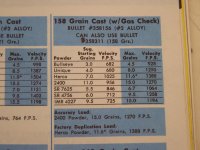

Pertinent to the OP's concerns, here is some data from the 45th edition of the Lyman handbook, copyright 1970:

I still have every manual I've ever purchased going back to 1975 (and it was a 1973 addition).

Old manuals can have some issues.

For example, the loads in the Hornady 3rd edition are considered to be a bit hot by some due to changes in SAAMI specs in some cartridges and a move away from copper crusher to piezoelectric pressure measurement).

On the plus side however, the older manuals will still provide load data long after the folks publishing the new manuals drop the older powders to make room to publish data for the newer powders.

There's an obvious need and demand to publish new data rather than repeat what was in older manuals, but the problem is excerbated by modern marketing. Unique for example gets slammed as "flaming dirt", a reputation it gets from being the go to powder for case bullet loads in many cartridges where the lube produces far more smoke than the powder.

It also tends to leave more residue in lighter loads where it doesn't burn as clean as it does in near maximum loads. However, it doesn't accumulate and shooters looking down a barrel and noting powder residue don't seem to grasp that it doesn't accumulate and will never be more than one shot dirty.

Then of course you have the misguided souls who do stupid stuff like 2000 round tests with no cleaning - apparently thinking that going 2000 rounds without cleaning will play some sort of role in their future. You know, like kids who watched Scooby Doo cartoons and Tarzan movies thought quick sand would play a much larger role in their adult lives.

None the less, that kind of dubious and misguided wisdom drives demand for newer cleaner burning powders that more often than not, do not offer any real advantage over the old standbys.