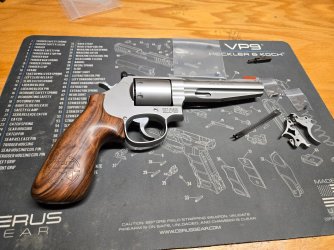

I got myself a 686 plus and after pulling the factory trigger I put it on the shelf and ordered TK custom DAO hammer and their trigger and extended firing pin.

Installed the hammer and the trigger, the trigger was rubbing a bit on one side so I installed a 0.002 shim on that side. Trimmed the strain screw until I got 6.8 pound trigger pull.

Now I have a very consistent trigger pull all the way until it hits the "wall". I hear 1st click followed by 2nd click and the trigger is smooth but the release of the hammer itself feels just a bit gritty and inconsistent. I have the Khunhausnen (sic?) revolver manual and will dig it out and go through it.

Meanwhile any hints at what I should look at?

Edit: I did not use the TK custom rebound slide since it would not let the hammer drop.

Installed the hammer and the trigger, the trigger was rubbing a bit on one side so I installed a 0.002 shim on that side. Trimmed the strain screw until I got 6.8 pound trigger pull.

Now I have a very consistent trigger pull all the way until it hits the "wall". I hear 1st click followed by 2nd click and the trigger is smooth but the release of the hammer itself feels just a bit gritty and inconsistent. I have the Khunhausnen (sic?) revolver manual and will dig it out and go through it.

Meanwhile any hints at what I should look at?

Edit: I did not use the TK custom rebound slide since it would not let the hammer drop.