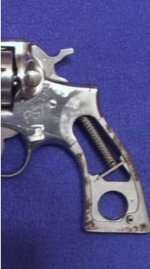

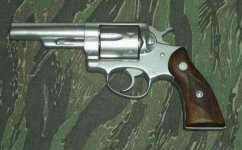

Hello everyone. I have recently come into possession of the below model 64-5. It has plenty of rust, grime, and scratches, but mechanically seems to be fine per to my novice eyes following the steps in this video:

[ame="https://www.youtube.com/watch?v=95xjizDOrcc"]https://www.youtube.com/watch?v=95xjizDOrcc[/ame]

The double action trigger pull in particular is incredibly smooth and fun to dry fire.

Given that the mechanical condition appears to be okay, my question is can the cosmetic issues be rectified and if so, how?

My only experience with removing rust was from an old axe head I found buried in my garden. I submerged it for a few days in white viengar and then washed it and coated it in baking soda. After several more washes I applied some WD-40 specialist corrosion inhibitor and since then it has looked and functioned perfectly.

Have any of you restored a stainless revolver such as this model 64-5? What techniques and products did you use?

Also, if anyone has any information about the manufacturing date of this firearm I would appreciate it. The serial number starts with BNW7.

Thank you everyone.

[ame="https://www.youtube.com/watch?v=95xjizDOrcc"]https://www.youtube.com/watch?v=95xjizDOrcc[/ame]

The double action trigger pull in particular is incredibly smooth and fun to dry fire.

Given that the mechanical condition appears to be okay, my question is can the cosmetic issues be rectified and if so, how?

My only experience with removing rust was from an old axe head I found buried in my garden. I submerged it for a few days in white viengar and then washed it and coated it in baking soda. After several more washes I applied some WD-40 specialist corrosion inhibitor and since then it has looked and functioned perfectly.

Have any of you restored a stainless revolver such as this model 64-5? What techniques and products did you use?

Also, if anyone has any information about the manufacturing date of this firearm I would appreciate it. The serial number starts with BNW7.

Thank you everyone.