ggibson511960

Member

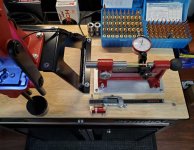

Like many reloaders I have a concentricity gauging rig complete with runout dial indicator. I must confess that I have used it little after coming to the conclusion that loaded ammunition found to have "excessive" concentricity went bang just like its more concentric stuff. You can surmise that I don't load for gilt edged accuracy. I have begun to wonder if it is possible to straighten cartridges found to be crooked. Brass is one of the more malleable metals and it would seem feasible to find the maximum axis of runout, slip the round into any old round hole and bend straight. Even a partial push into a resizing die would seem to improve neck to side wall concentricity and alignment. Has anyone tried something like this?