This is a follow up to my previous post. I came up with this idea after wanting a reasonable reproduction of a Model 57 first year 6 inch case with a velvet liner, a difficult case to find. These cases had a molded high denisty foam backing, not styrofoam or a plastic liner. I tried shaping hard foam with a dremel tool but that was very difficult and messy.

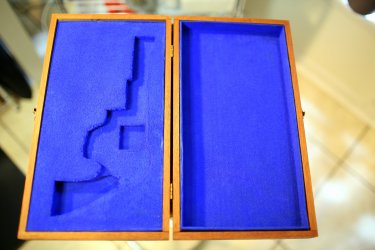

This is the interior I built for the Model 57 using a factory box.

I then built a couple of custom cases. Here's the product I used. It's designed for a toolbox liner. It's 1 inch thick and has 4 quarter inch layers. As you cut it, each layer can be pulled off, to create different depths. It cuts easily and is very durable and strong. It has a small amount of cushion to it, so it's not stiff.

A normal case interior with gun and tools can be made in a few hours, especially after you get some practice.

My project is a Model 53 .22 Jet custom case, 8 3/8, which did not come with the original box. I cut the first piece to fit the box with a sharp kitchen knife using a granite counter edge as a guide.

Then I outlined the gun with a chalk marker and cut the first shape about 1/2" deep with a break away wallpaper knife.

After cutting the outline, just peel away the first 1/4" layer.

The next layer is for the receiver, cylinder and grips. Cut and pull away one more layer.

Then one more layer for the grips and cylinder. Finally the target grips and cylinder go all the way through.

Then it's just a matter of laying out your other items. The cleaning rod and screwdriver are just one layer.

I also, in this case, built a little compartment for the .22 inserts. I made the compartment from leather and chipboard. It will have a fancy lid when I'm finished. The wooden block shown is to support my lid.

In part 2, I'll show you how to cover the case with material.

This is the interior I built for the Model 57 using a factory box.

I then built a couple of custom cases. Here's the product I used. It's designed for a toolbox liner. It's 1 inch thick and has 4 quarter inch layers. As you cut it, each layer can be pulled off, to create different depths. It cuts easily and is very durable and strong. It has a small amount of cushion to it, so it's not stiff.

A normal case interior with gun and tools can be made in a few hours, especially after you get some practice.

My project is a Model 53 .22 Jet custom case, 8 3/8, which did not come with the original box. I cut the first piece to fit the box with a sharp kitchen knife using a granite counter edge as a guide.

Then I outlined the gun with a chalk marker and cut the first shape about 1/2" deep with a break away wallpaper knife.

After cutting the outline, just peel away the first 1/4" layer.

The next layer is for the receiver, cylinder and grips. Cut and pull away one more layer.

Then one more layer for the grips and cylinder. Finally the target grips and cylinder go all the way through.

Then it's just a matter of laying out your other items. The cleaning rod and screwdriver are just one layer.

I also, in this case, built a little compartment for the .22 inserts. I made the compartment from leather and chipboard. It will have a fancy lid when I'm finished. The wooden block shown is to support my lid.

In part 2, I'll show you how to cover the case with material.