"Floor Plates"----a closer look

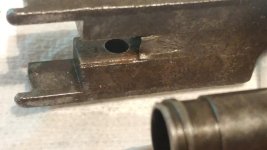

My first inquiry into "floor plates" considered manufacturing processes---only. I decided those which had them had "cam slots" which were milled from the top down---and those that didn't had cam slots milled from back to front. It made sense. I stopped.

I started another such inquiry---just now. I examined all my top breaks. Here's what's what----along with some commentary---which may or may not be sound.

Matthew's large frame .44 DA has one, ergo it stands to reason all large frame guns have them. Really?!! I have 4 NM #3 Targets (same/similar frames/same/similar barrels). They were shipped in 1893, 1894, 1896, and 1902. NONE of them have "floor plates". HUH?!!

I have 4 1st Model SS's (small frames). They were shipped in 1895, 1900, 1902, and 1905. ALL of them have "floor plates". Hmmmmmm??

I have 4 2nd Model SS's (same small frame/same barrel). They were shipped in 1909, 1909, 1910 and 1910. ALL of them have "floor plates". Okay.

I have 1 Model of '91 target revolver---small frame/same size barrel forging---parent of the SS's above. It was shipped in 1910. It DOES NOT have a "floor plate". Hmmmmmmm??---again.

I have 4 3rd Model SS's---small frame, more importantly---same barrel forging as the 1st's/2nd's above. The first two were shipped in 1915 and 1916. They have "floor plates". The last two were shipped in 1923 and 1924. They DO NOT have "floor plates".

That's the end of my top breaks. At this point, I was contemplating walking down to the river, and jumping in.

Given my bent to think about how these things were made---and at what point might one (having made a mistake) pitch the mistake and start over, I immediately jumped to the conclusion these "floor plates" were a repair procedure----the barrel was improperly jigged (to mill from back to front)----the milling bit ran out the top---and-------"floor plate" to the rescue. It made sense---at least a little.

Given the total lack of statistical analysis validity represented by this small sample, it's quittin' time---for now at least.

Having said all that, I'm starting to see why Mr. Jinks ignored my question on this topic---although it would display a modicum of couth to simply respond with an "I don't know."

Ralph Tremaine