OK, all I can say to that is that I changed a lot of 1911 sights and they came out easier to the left. That was the conventional wisdom back in the last century.

ETA: I've had a new Colt series 70 that needs better than factory sights in the safe for ~40 years. The rear sight came out right to left. It wasn't going anywhere left to right. I do recall one 1911 that needed it's rear sight removed with a milling machine. I'm gonna call Novak and have him install a dovetail front to match the rear sight I installed. (Yeah, I can-probably-practice up and do it, but don't want to mess things up.) Back in the day I only did 2 and learned to cut the dovetail a wee smidgen deep and adjust the top surface to get the proper depth. NO, I didn't learn that on customers guns.

That said, a5werkes does have a point in that the manufacturers cut their sights and dovetails straight across. HOWEVER, there has to be some differences in dimensions* to get the proper fit and there are also tolerances in play. Finally, there's the poor soul who has to make the sight fit in the slot. Somehow.

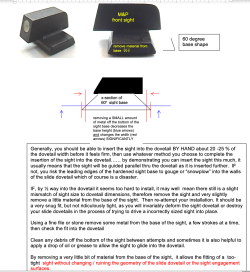

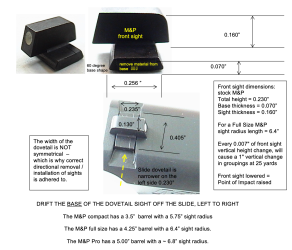

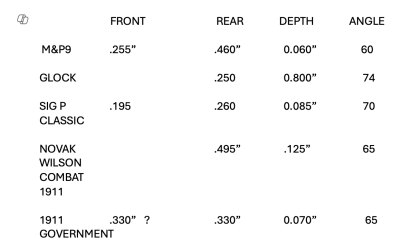

Tip: try new sights in the dovetail and see if they go further in on one side than the other. If so, insert from that side. Also, per one of our members, if it doesn't fit, try filing the bottom of the sight. That will drop the sight down and make it fit better-design permitting. It's way easier and a whole lot less expensive if you mess up a sight than the barrel/slide. While most dovetails are 60 degrees, 1911 dovetails are-mostly-65 degrees.

*General practice is that holes have to be larger than nominal size, but not smaller. What goes into those holes has to be smaller than nominal size, but not larger. Doesn't apply when you want a press/interference fit.