DocSkinner

Member

- Joined

- Jan 5, 2015

- Messages

- 16

- Reaction score

- 8

SO first, I know true end shake (cylinder movement while locked) is a key to accuracy. And that is not what I am talking about. this has no end shake when locked.

And know that GENERALLY a little cylinder movement on the yoke with the yoke open is not a problem.

but - when the cylinder hits the forcing when closing unless it is held rearward, that becomes a problem!

There seems to be shims for everywhere else on a SW revolvers except there!

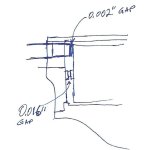

Now may be to long of forcing cone (another issue - CG is only ~0.002 snug or a slip all way around, .003 will not fit any positions), so that is too tight, but not sure getting that opened up to minimum of .003 or up to .006 max will clear enough as when closed and locked there is a 0.016" gap between cylinder and yoke bosses. See attached drawing (yes, crude, I know)

Forcing scone stands proud 0.125".

so opening CG to .006" would give .004" more clearance, but cylinder can still move 0.016. So counting CG, its ~.014 of a problem now, and with .006" CG fix on forcing cone, would still leave ~0.010 interference.

Yoke fit seems perfect. closed there is no discernible edge transitioning from the yoke to frame or vice versa

Is it normal to have that much forward/back play with cylinder open?

are there specs for how tall the cylinder (0.091") and yoke (0.0565") bosses should be so I can see if someone tried a hack gunsmithing job on it?

Best fix if not a cylinder/yoke bearing/shim?

Specs:

Bought used 3" 657. product code 103951 (Special order 6203) so it was an original 3"

And know that GENERALLY a little cylinder movement on the yoke with the yoke open is not a problem.

but - when the cylinder hits the forcing when closing unless it is held rearward, that becomes a problem!

There seems to be shims for everywhere else on a SW revolvers except there!

Now may be to long of forcing cone (another issue - CG is only ~0.002 snug or a slip all way around, .003 will not fit any positions), so that is too tight, but not sure getting that opened up to minimum of .003 or up to .006 max will clear enough as when closed and locked there is a 0.016" gap between cylinder and yoke bosses. See attached drawing (yes, crude, I know)

Forcing scone stands proud 0.125".

so opening CG to .006" would give .004" more clearance, but cylinder can still move 0.016. So counting CG, its ~.014 of a problem now, and with .006" CG fix on forcing cone, would still leave ~0.010 interference.

Yoke fit seems perfect. closed there is no discernible edge transitioning from the yoke to frame or vice versa

Is it normal to have that much forward/back play with cylinder open?

are there specs for how tall the cylinder (0.091") and yoke (0.0565") bosses should be so I can see if someone tried a hack gunsmithing job on it?

Best fix if not a cylinder/yoke bearing/shim?

Specs:

Bought used 3" 657. product code 103951 (Special order 6203) so it was an original 3"

Attachments

Last edited: