Going by the FAQ post made by 500 Magnum Nut -->

FAQ at no time should the ball drop below the window otherwise it can get hung up. A copy and paste of his text from that post;

"Make sure that when the trigger pulls it down, that it does not pull the ball out of the frame window. If you leave it set where the ball drops below the opening, it can get offset to one side and hang up inside the frame.

When originally fitted, the stop is timed so that at no time the top of the ball drops below the edge of the window in the frame. If it does, it can stick in the down position."

I have one shot at this before ruining the part, now so close with everything else fitting perfectly with such a wonderful lockup achieved I hate to ruin the catch and have to start over.

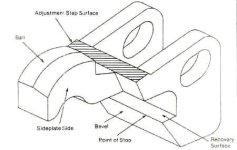

Wouldn't cutting the Bevel back also achieve the same? My concern was and is, cutting the Bevel back, does that effect timing elsewhere during the cycle? Same goes with the Recovery Shelf,

why they named it the Recovery Shelf might give a hint but that's knowledge lost to me. I understand each part has an effect on how another part operates and timing is critical, one part out of spec can have a negative effect, two or more and you have stacking. These are finely designed intricate pieces, very intriguing to me and I love to find out how machinery works, always have. It's one of the things that drew me to firearms as a youth and started me tinkering with them, I've always done as much of my own smithing as I can, a few times it bite me but more times then not I've made my own repairs, even those times I failed I gained more knowledge.

Just last night I discovered there is the book by Kuhnhausen, the 5th edition S&W revolver shop manual, I'll get one ordered but in the mean time I was hoping a S&W smith might answer my question, like to finish this project in the next couple days.

A little of my background, my Father was a tool and die maker, he made prototype parts and tooling for Smith Corona typewriters, tiny parts... He taught me as a lad how to use and read a micrometer, gave me one of his spares to learn with, he also taught me how to read and draw blueprints. From there I always had an interest in anything mechanical. At an early age I wanted to be a machinist like my Father, my Hero. I took two years of Machine Shop trade school classes but as a teenager with a drivers license my passion also turned to hot rods. I ended up working on cars all my life but still have that machinist passion, my machinist skills came into play when rebuilding engines and transmissions, an overlap of both passions. Now that Dad has passed, I have his machinist tools along with those I used on the job. And now retired, I love to spend time tinkering in my shop. Taking an out of time 27, installing a new oversized hand and cylinder stop to make it perfect has been very, very satisfying.