I'm recovering from an unplanned rapid weight loss courtesy of the e. coli diet and was looking for something to do, so I started thinking about my stable of K-frame rimfires and how picky they are.

For the purposes of this exercise, we're only focusing on .22 LR revolvers. I have a 48-2 in .22 mag (A Little Harry) but that one ejects everything I put into it just fine as long as I keep the chambers clean. The .22 LR guns are the picky ones....or at least 3 of them are.

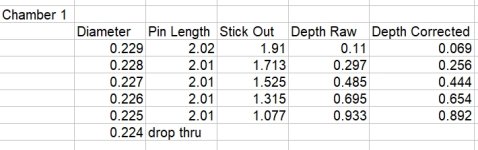

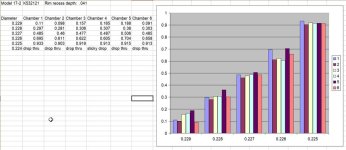

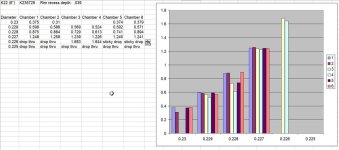

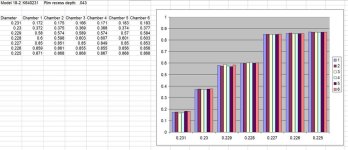

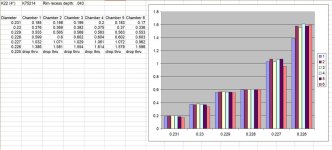

Our subjects today are a 6" 17-2 from 1963, a 6" K22 from 1955, a 4" 18-2 from 1965, and a 4" K22 from 1949.

The 17-2 is the only one that will chamber, fire, and eject all brands of .22 LR ammo. The pair of 4" guns work fine with Federal and Remington ammo, but Winchester and CCI ammo sticks badly on ejection. By "badly" I mean poke them out individually with a cleaning rod being struck by a screwdriver handle. The 6" K22 is by far the pickiest one of the bunch. It will only eject Remington ammo and then only if the temperature is below 80 degrees.

For the purposes of this exercise, we're only focusing on .22 LR revolvers. I have a 48-2 in .22 mag (A Little Harry) but that one ejects everything I put into it just fine as long as I keep the chambers clean. The .22 LR guns are the picky ones....or at least 3 of them are.

Our subjects today are a 6" 17-2 from 1963, a 6" K22 from 1955, a 4" 18-2 from 1965, and a 4" K22 from 1949.

The 17-2 is the only one that will chamber, fire, and eject all brands of .22 LR ammo. The pair of 4" guns work fine with Federal and Remington ammo, but Winchester and CCI ammo sticks badly on ejection. By "badly" I mean poke them out individually with a cleaning rod being struck by a screwdriver handle. The 6" K22 is by far the pickiest one of the bunch. It will only eject Remington ammo and then only if the temperature is below 80 degrees.