NH Old School

Member

- Joined

- Feb 19, 2015

- Messages

- 65

- Reaction score

- 67

On 12/11/2015 I started a thread regarding an old M&P I had just picked up that had the old style hammer block. This gun was probably made in sometime in the 1920's. My issue was that the hammer block was broken. I wasn't too concerned about that, since this will be a range gun only, but I was more interested in the idea that a properly working hammer block of that earlier type might improve the carry up, which was pretty bad on the revolver in question.

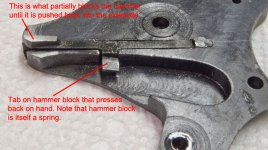

Just to review a little, the hammer blocks on the older guns work entirely differently than on current guns. Not sure when the change was made, but I have a 1959 Model 27 with the new style (works off the rebound slide), and a 1940 38-44 with the old style (spring set into the sideplate, partially blocks the hammer, deactivated by the hand, which has an inclined plane type of surface at the rear for that purpose). I repeat, they are entirely different parts and work completely differently.

Well, the replacement part arrived today, and I installed it. My theory was right. It does indeed much improve the carry up, to the point where it is now absolutely satisfactory. Slow cocking, either with the trigger or the hammer (double or single action) results in reliable lockup before the hammer falls on all chambers. Prior to installing the new hammer block there was not lockup in either mode on any chamber unless either the trigger or hammer was pulled very vigorously, more so than one would normally do in shooting, relying on momentum to carry the cylinder far enough for the cylinder stop to fall into a notch. Installing the new hammer block has made a difference of night and day in carry up.

I originally thought this might be the case because the hammer block, being itself a spring, pushes the hand to the left while the hand is pushing the hammer block to the right and into the sideplate. This makes any sideplay in the hand irrelevant, as it is actively pressed into the ratchet on the extractor.

So I learned something today. And I have a safer and better working gun to show for it.

Just to review a little, the hammer blocks on the older guns work entirely differently than on current guns. Not sure when the change was made, but I have a 1959 Model 27 with the new style (works off the rebound slide), and a 1940 38-44 with the old style (spring set into the sideplate, partially blocks the hammer, deactivated by the hand, which has an inclined plane type of surface at the rear for that purpose). I repeat, they are entirely different parts and work completely differently.

Well, the replacement part arrived today, and I installed it. My theory was right. It does indeed much improve the carry up, to the point where it is now absolutely satisfactory. Slow cocking, either with the trigger or the hammer (double or single action) results in reliable lockup before the hammer falls on all chambers. Prior to installing the new hammer block there was not lockup in either mode on any chamber unless either the trigger or hammer was pulled very vigorously, more so than one would normally do in shooting, relying on momentum to carry the cylinder far enough for the cylinder stop to fall into a notch. Installing the new hammer block has made a difference of night and day in carry up.

I originally thought this might be the case because the hammer block, being itself a spring, pushes the hand to the left while the hand is pushing the hammer block to the right and into the sideplate. This makes any sideplay in the hand irrelevant, as it is actively pressed into the ratchet on the extractor.

So I learned something today. And I have a safer and better working gun to show for it.