I've been working on finding exactly when the early M&P hand ejectors were converted to smokeless powder then more importantly when the improvement was made to the forcing cone to handle various "increased"powder loads.

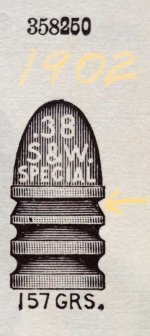

The first change was definitely in 1902 the same year the first Smokeless bullet was introduced: Photo 1

It's the next change that took a lot of research to confirm.

By my research notes that change took place in late 1914/1915 time frame. Approximately serial number 250,000 range.

A significant beefing up of the forcing cone shows up in that serial number range. See photos.

I knew it took place but wasn't sure when it occurred.

In my opinion any hand ejector model manufactured prior to 1915 should only use low standard smokeless pressure loads that were listed at that time in early reloading manuals.

Later hand loads increased to as much as 18,000 psi. That is an increase from the early smokeless loads around 11,000 psi.

The early loads did NOT list a variety of bullet weights and powder selection like later listings. This was the source of forcing cone failure on the early guns. Put simply; too much pressure from more modern loadings.

Murph

The first change was definitely in 1902 the same year the first Smokeless bullet was introduced: Photo 1

It's the next change that took a lot of research to confirm.

By my research notes that change took place in late 1914/1915 time frame. Approximately serial number 250,000 range.

A significant beefing up of the forcing cone shows up in that serial number range. See photos.

I knew it took place but wasn't sure when it occurred.

In my opinion any hand ejector model manufactured prior to 1915 should only use low standard smokeless pressure loads that were listed at that time in early reloading manuals.

Later hand loads increased to as much as 18,000 psi. That is an increase from the early smokeless loads around 11,000 psi.

The early loads did NOT list a variety of bullet weights and powder selection like later listings. This was the source of forcing cone failure on the early guns. Put simply; too much pressure from more modern loadings.

Murph

Attachments

Last edited: